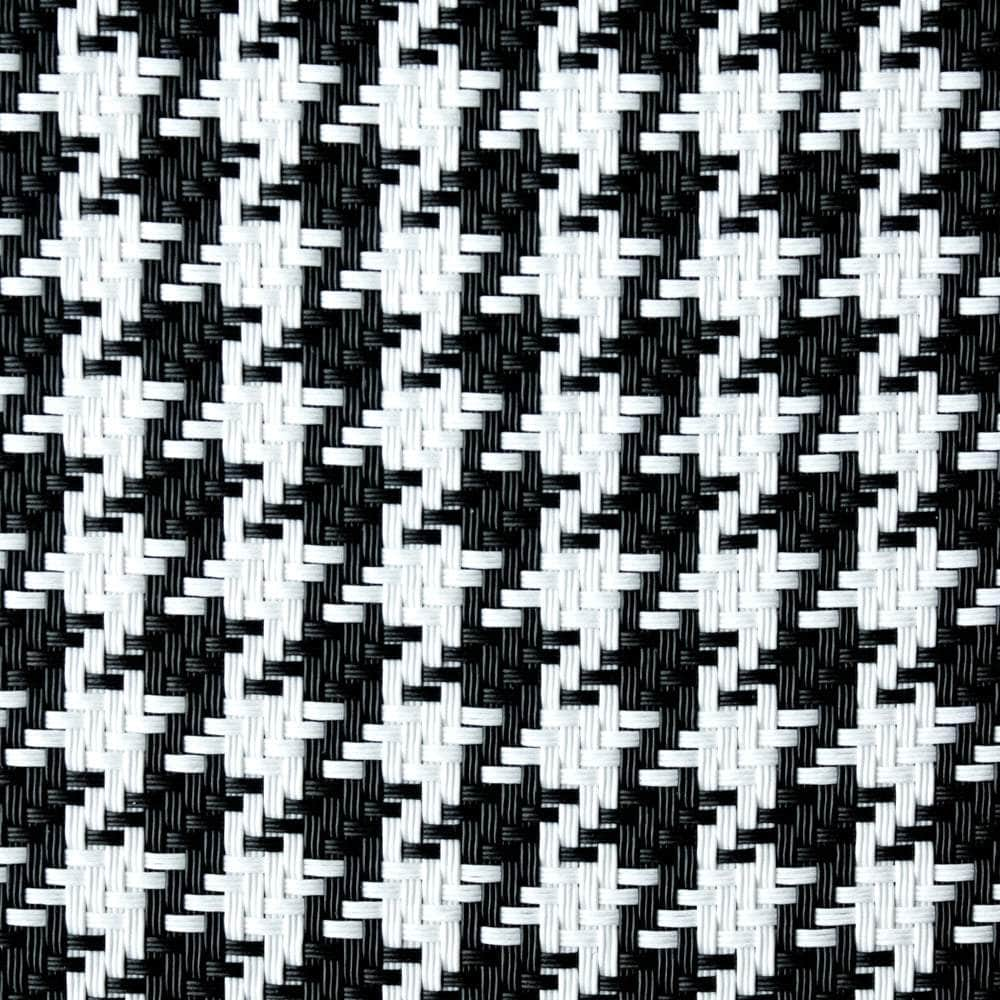

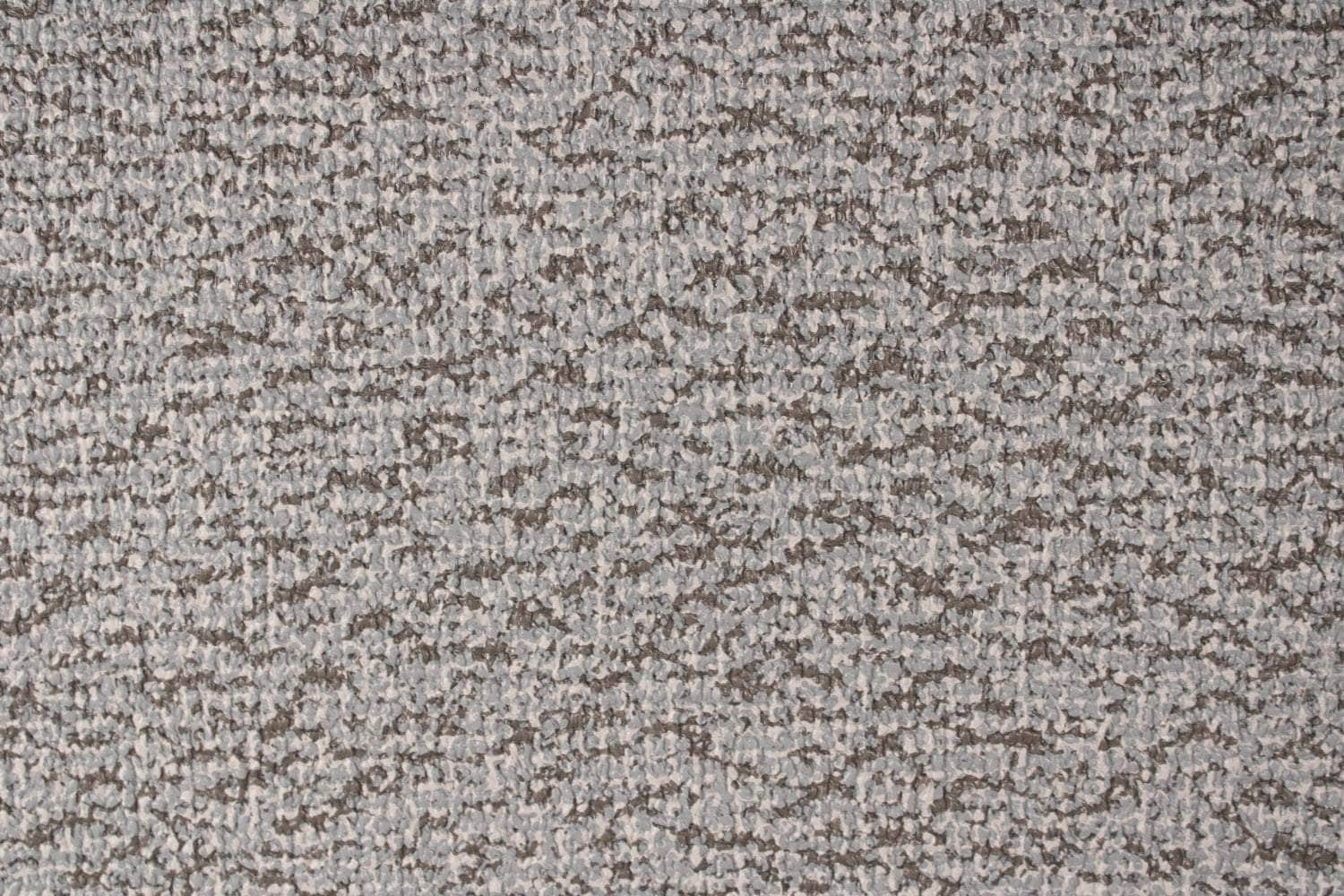

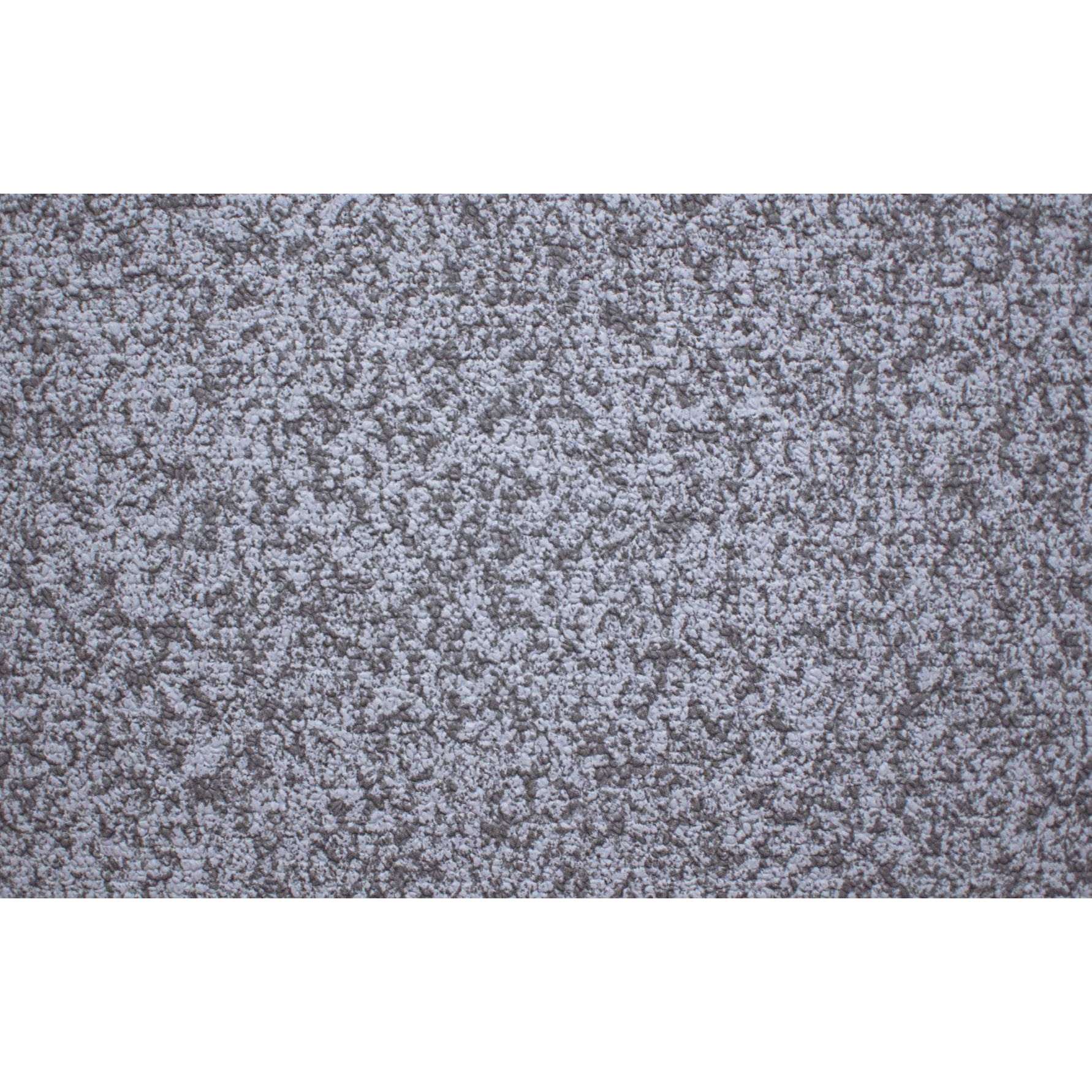

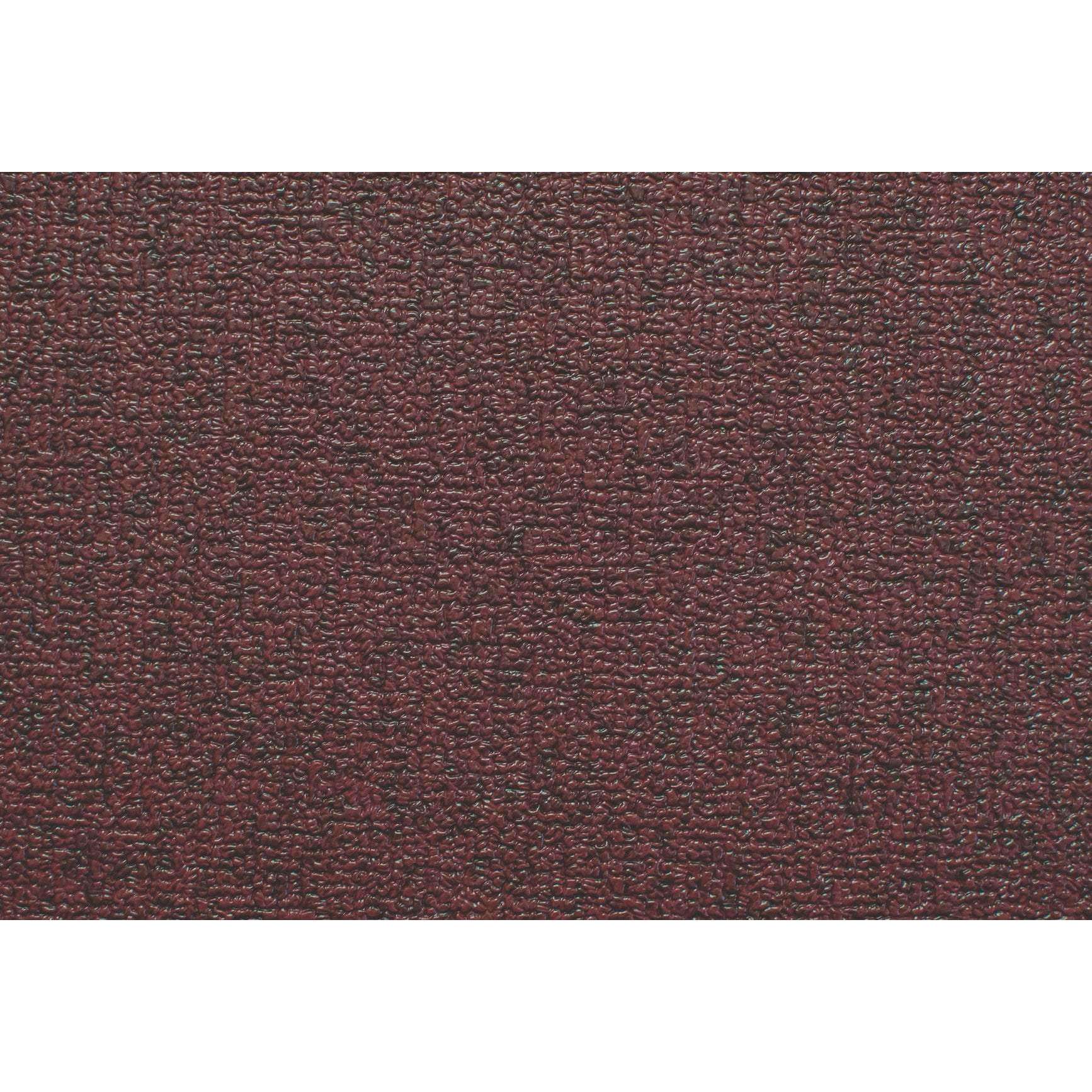

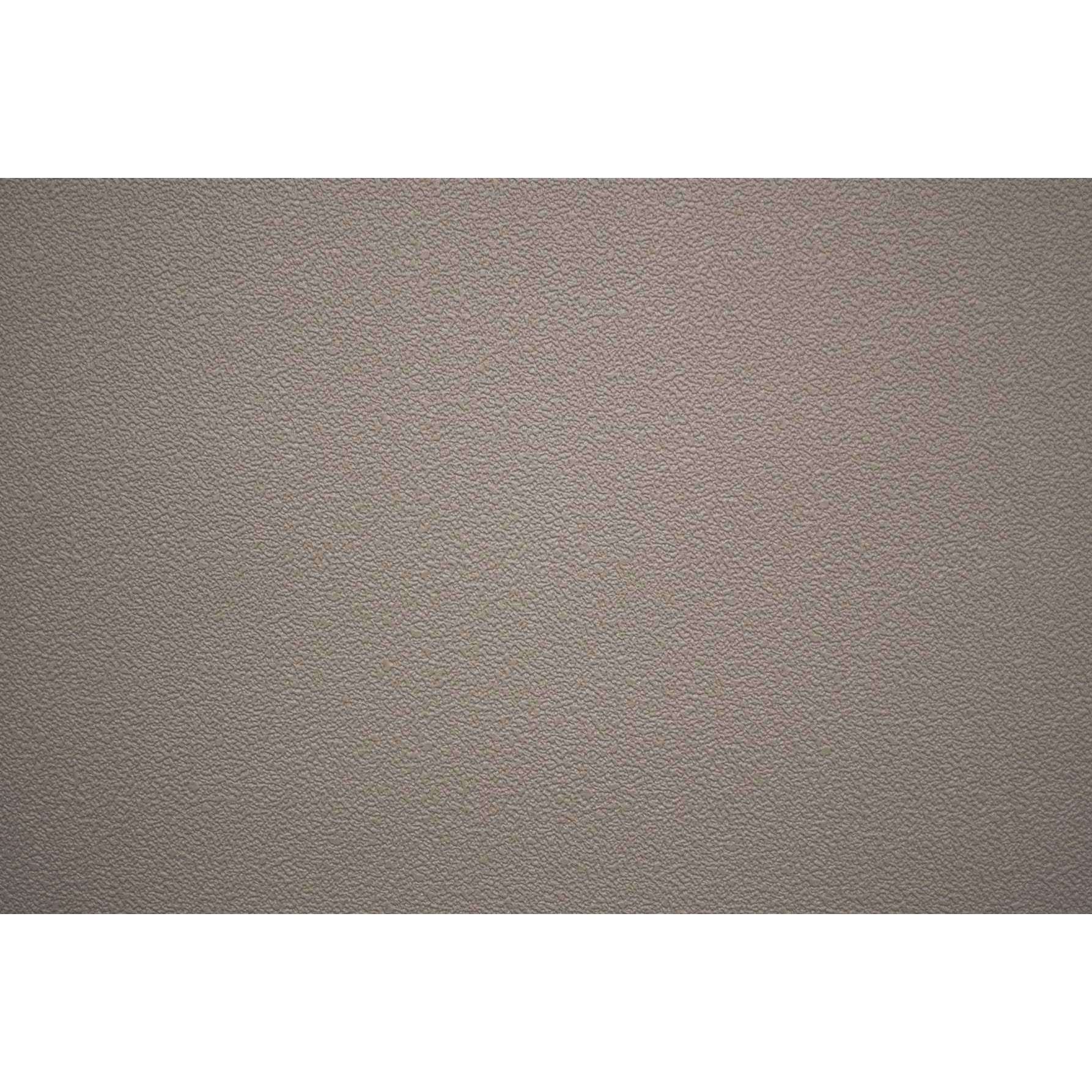

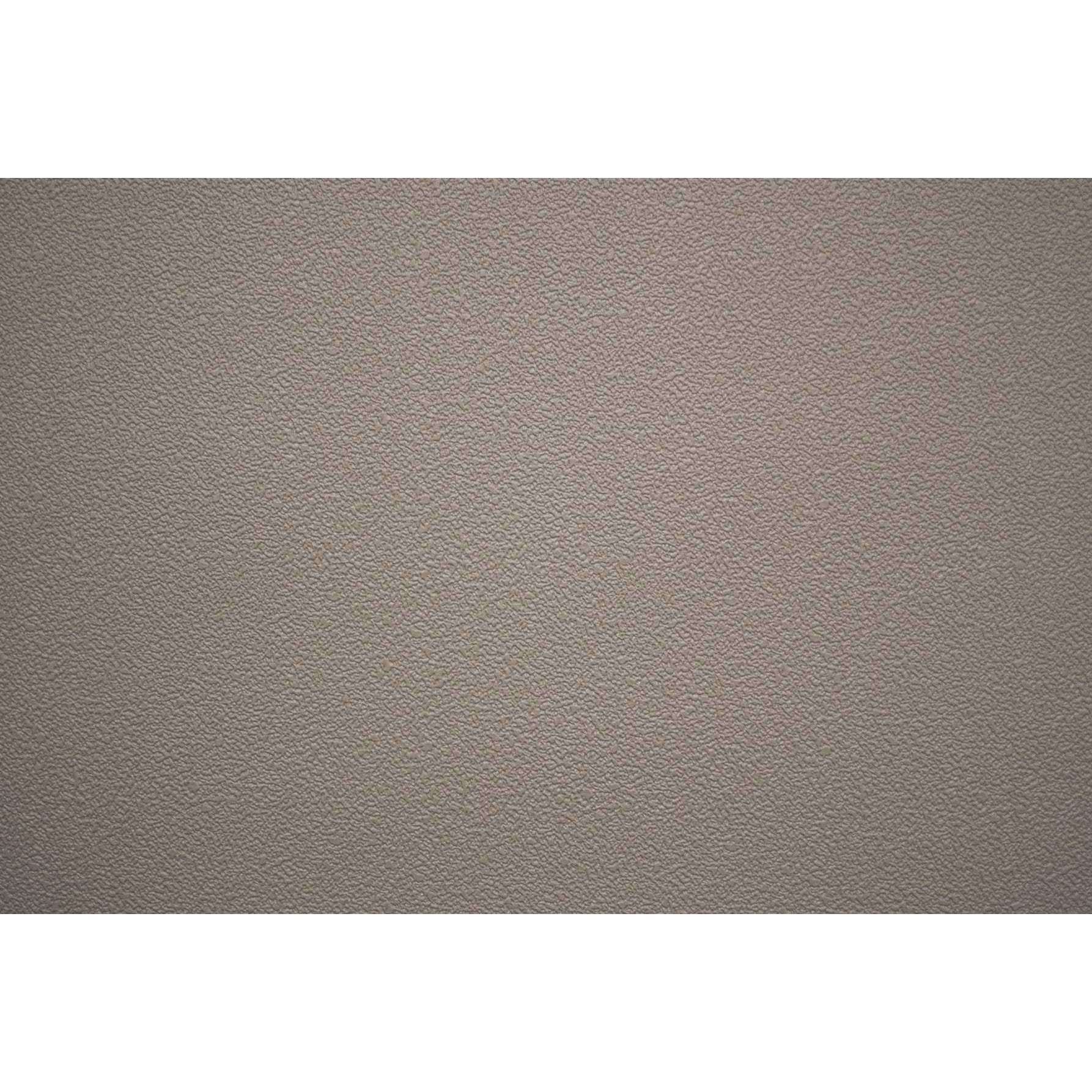

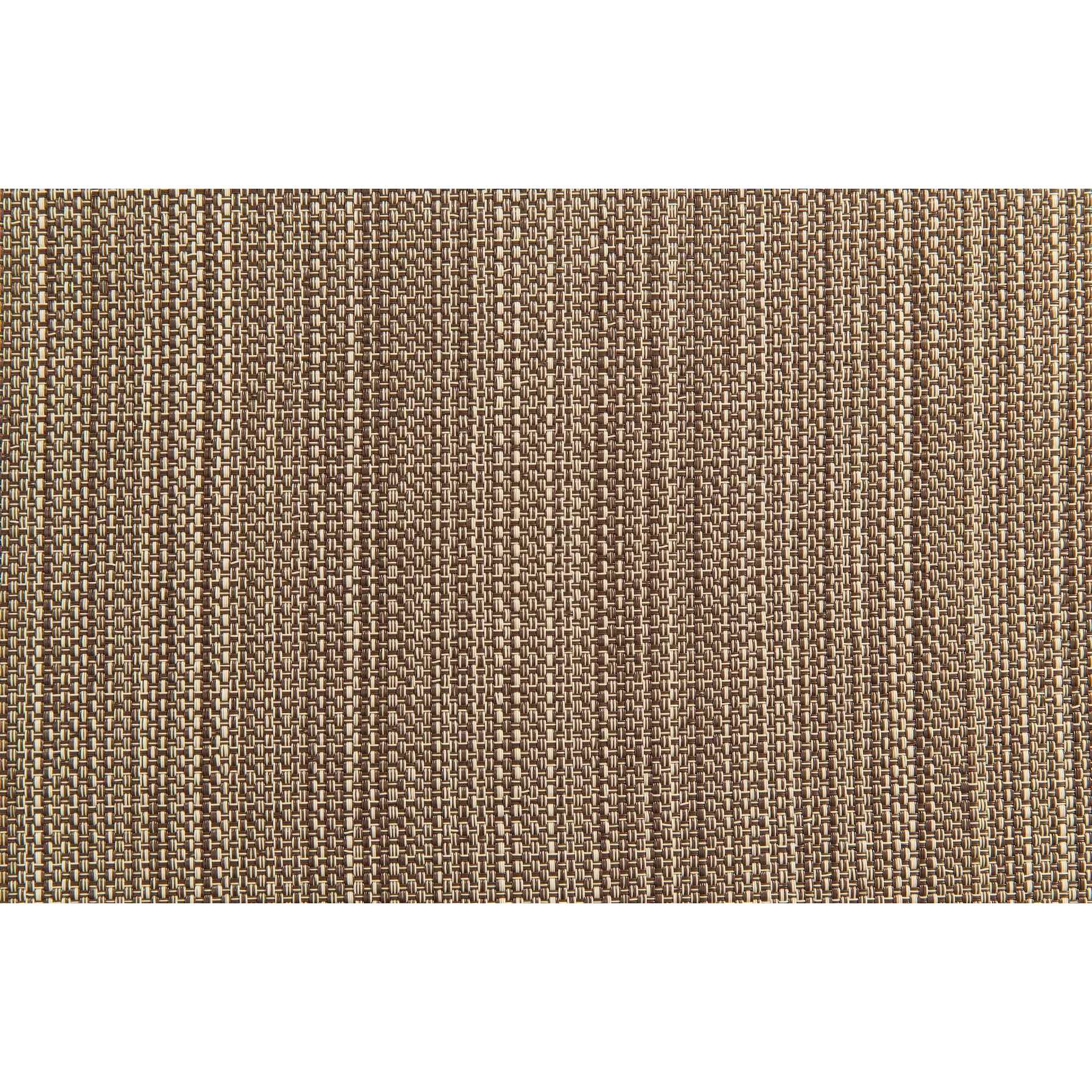

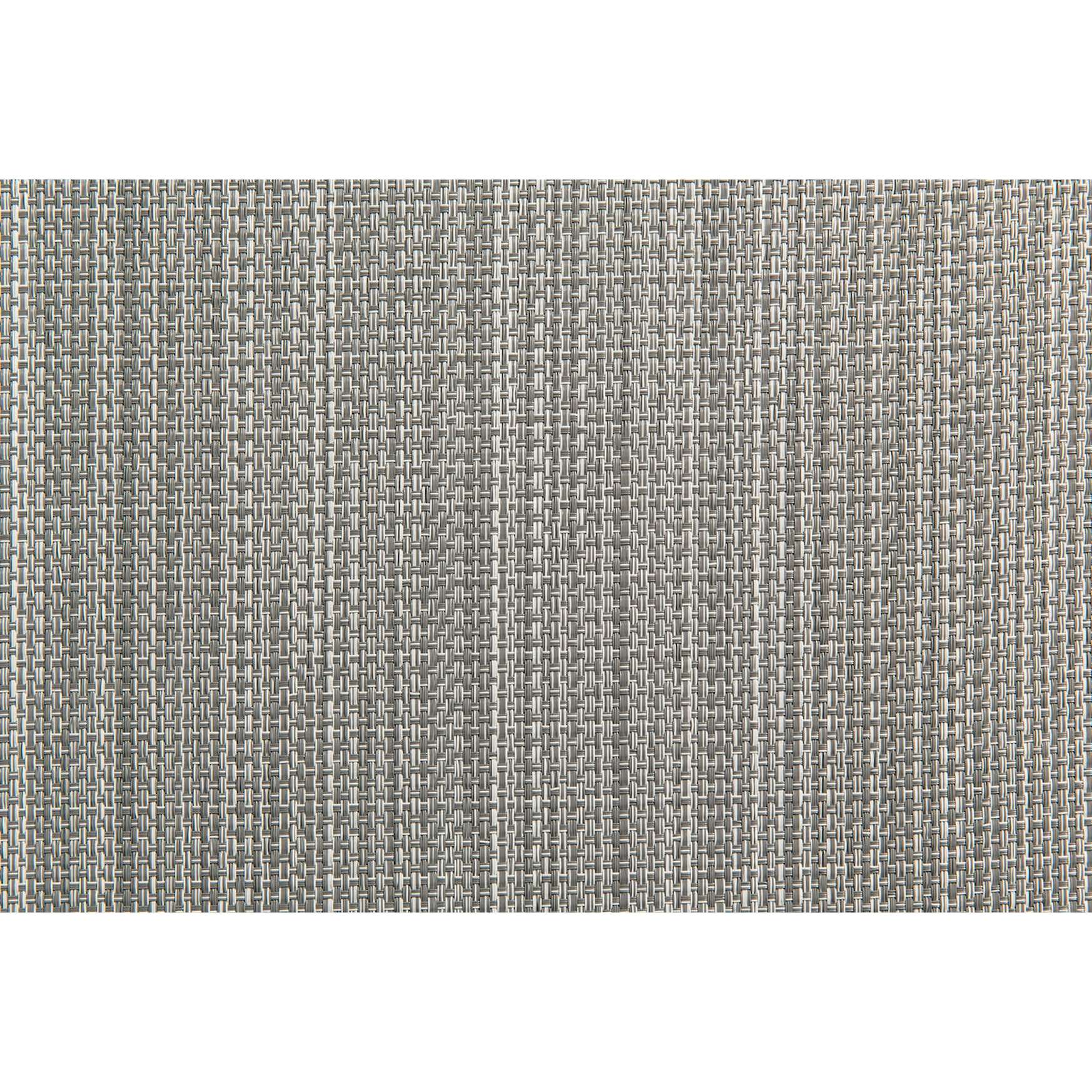

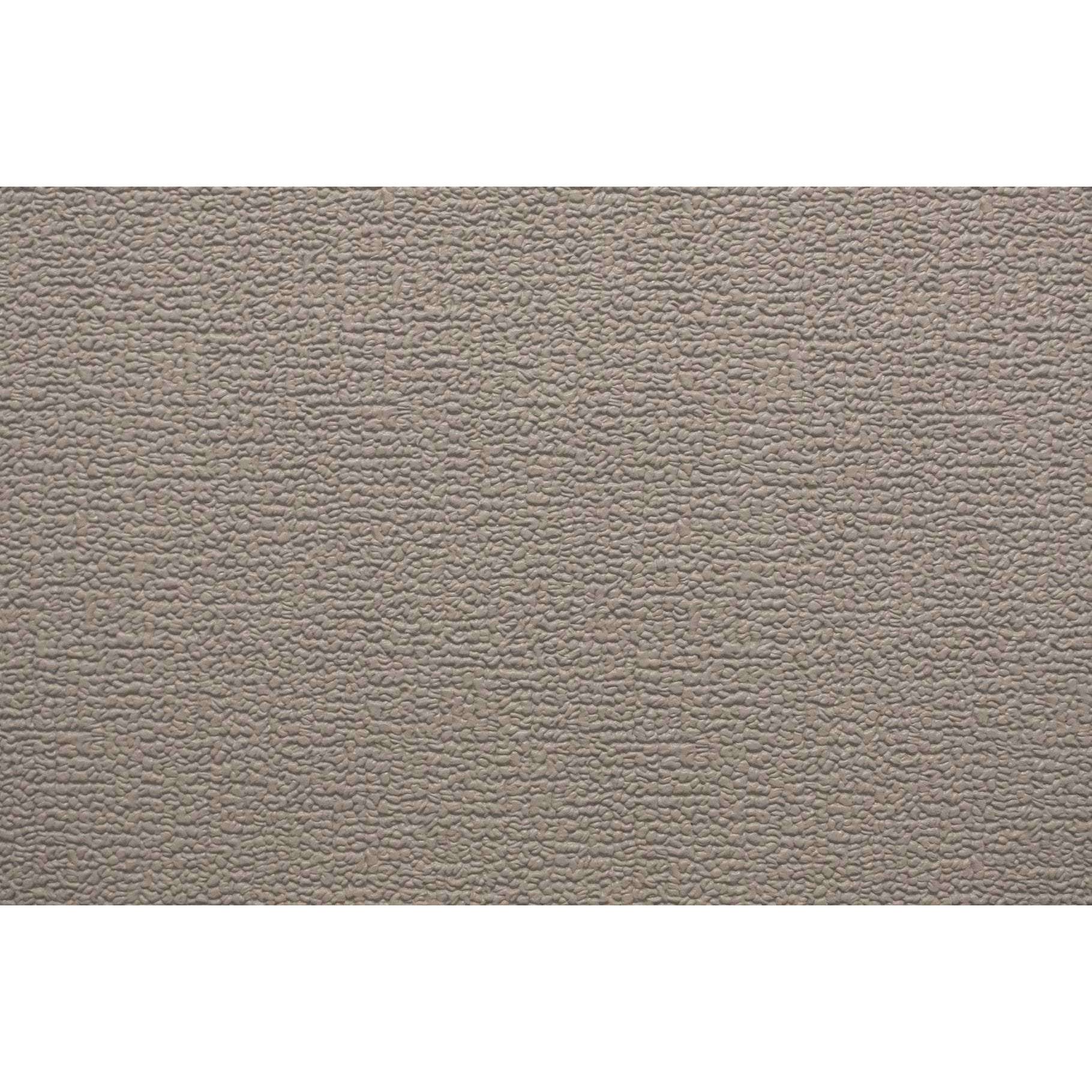

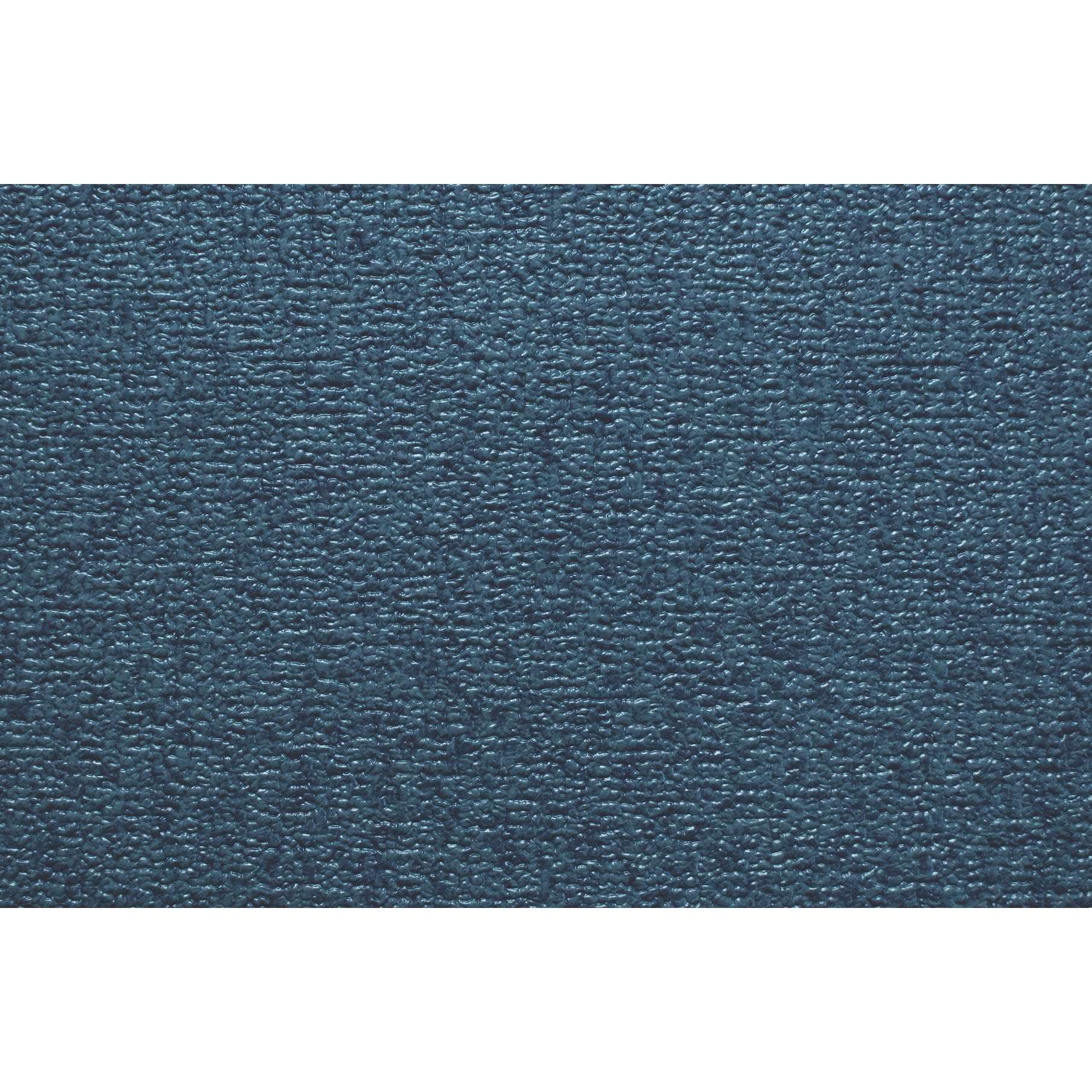

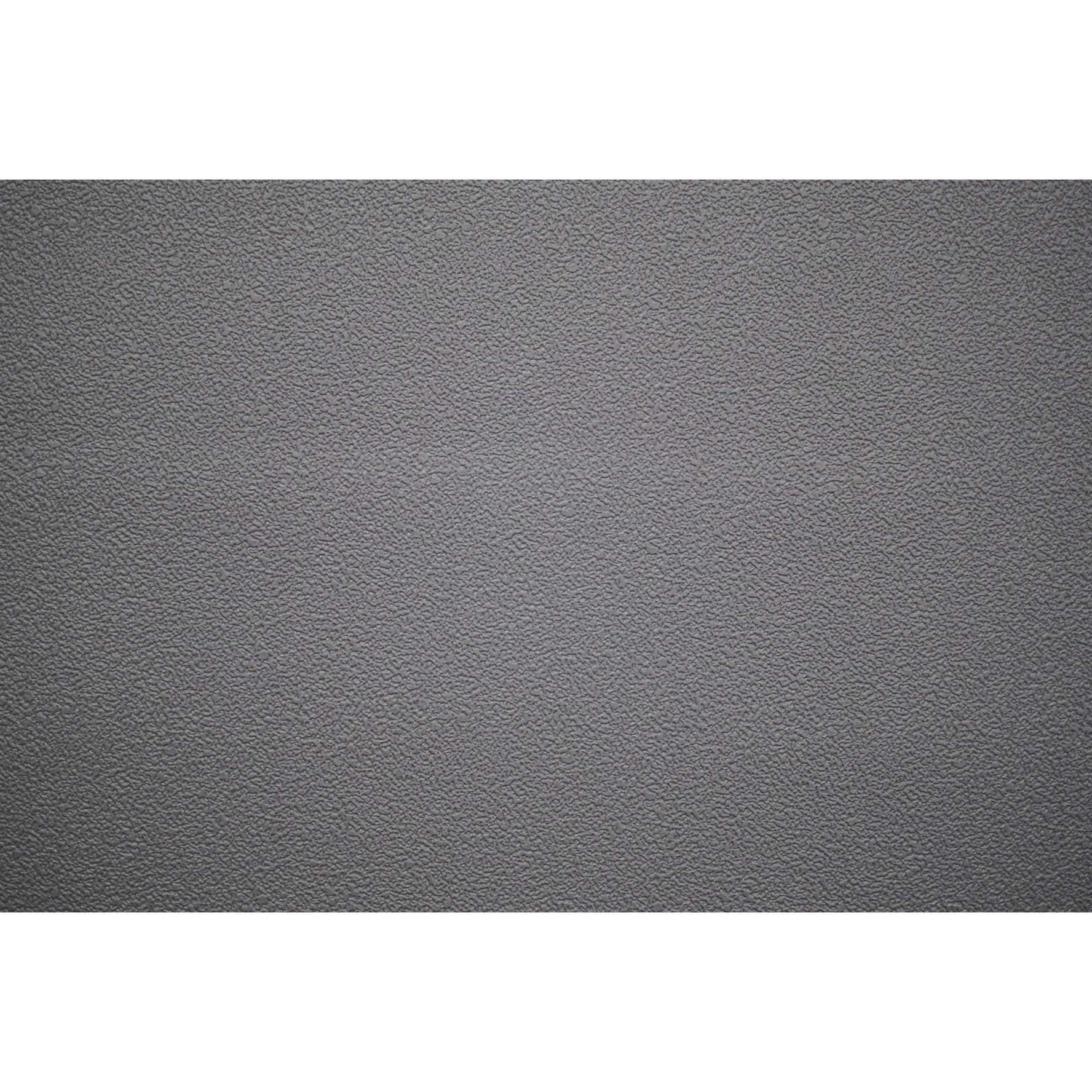

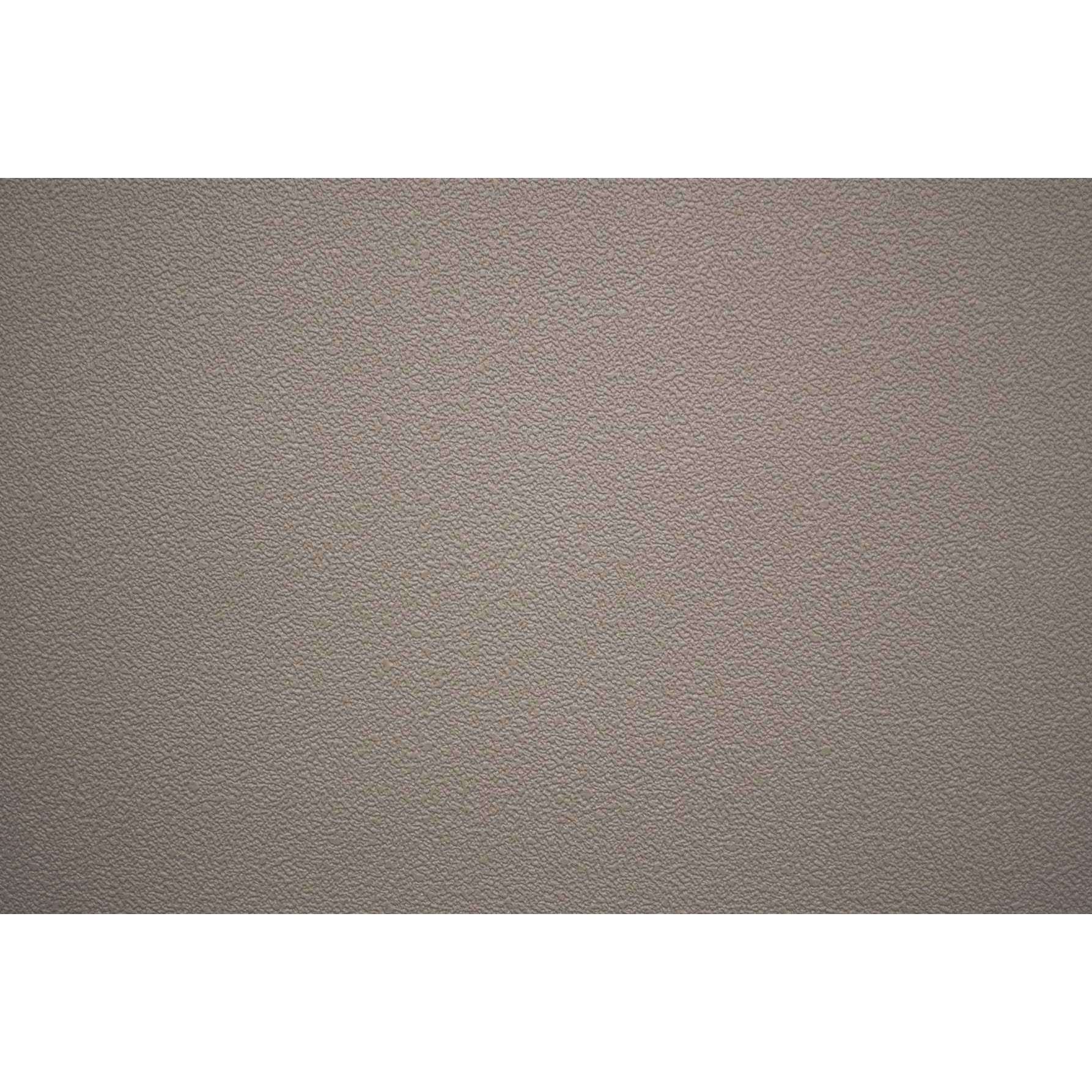

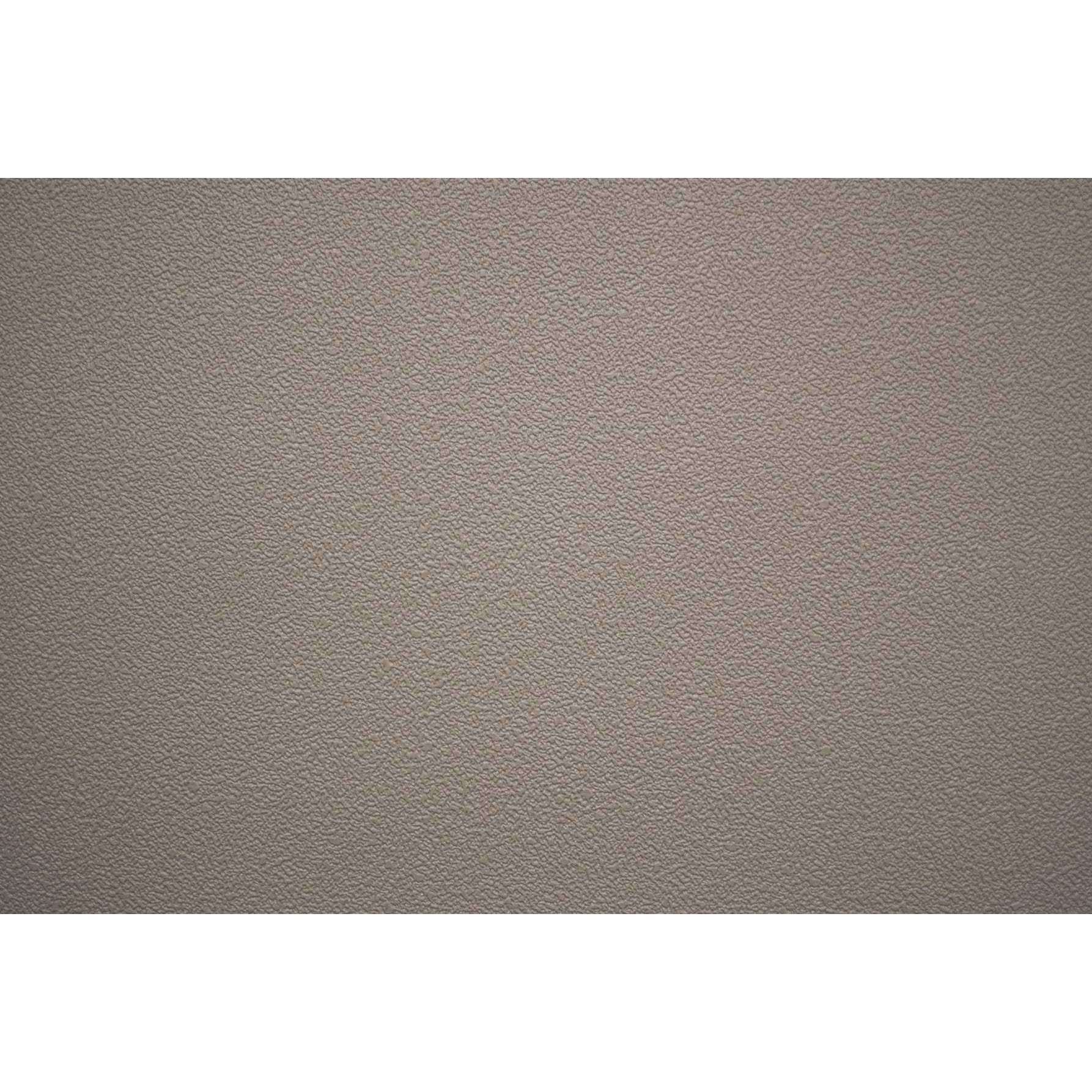

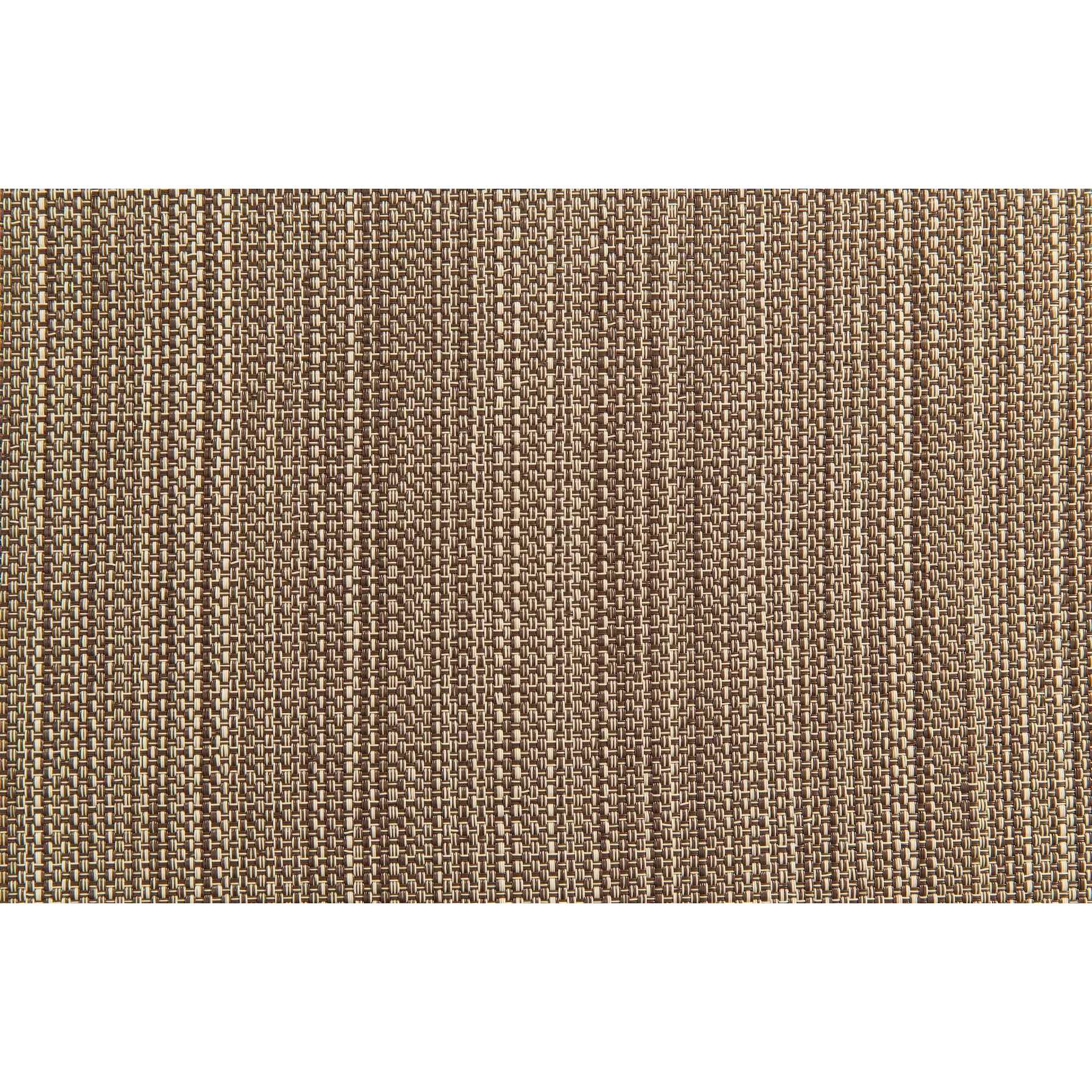

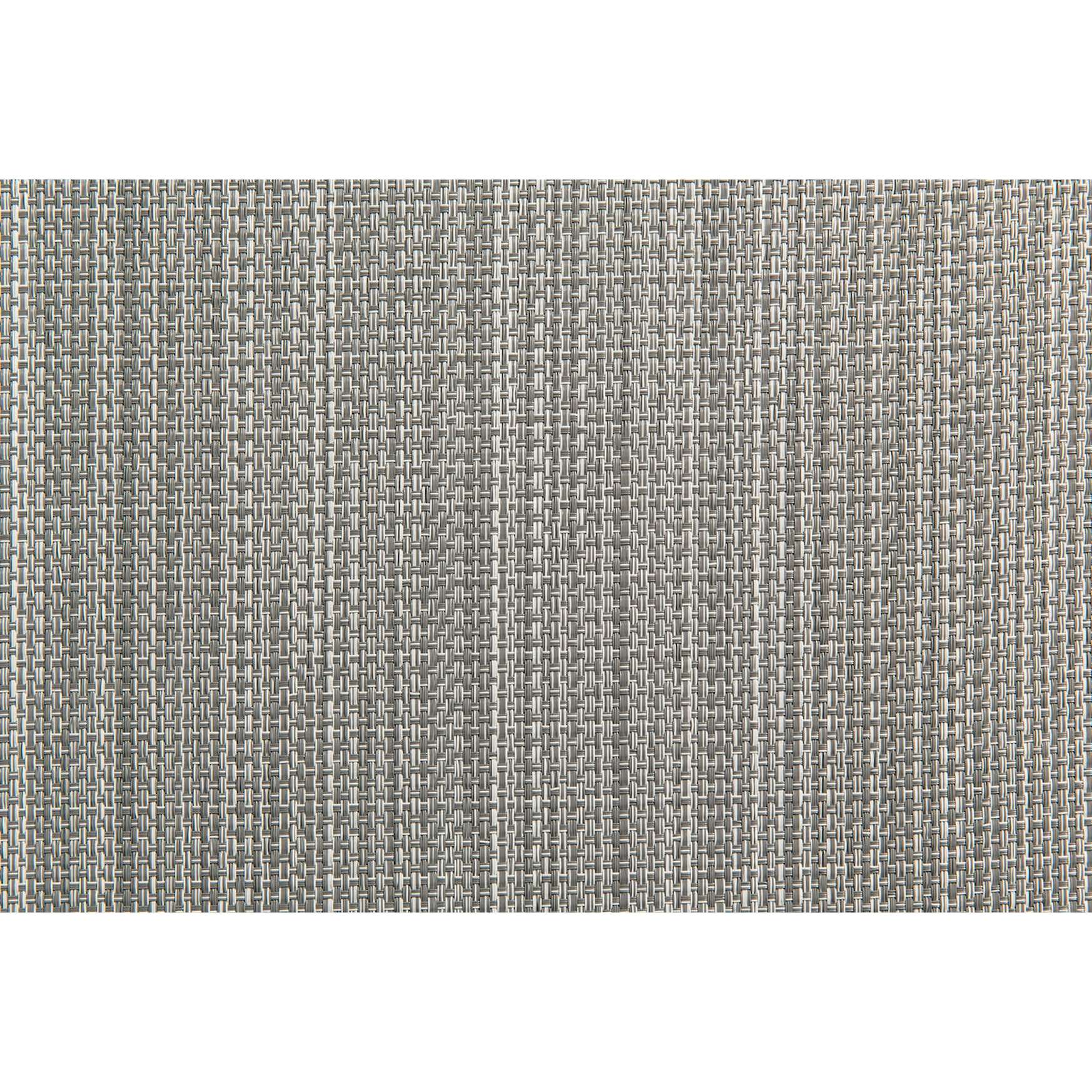

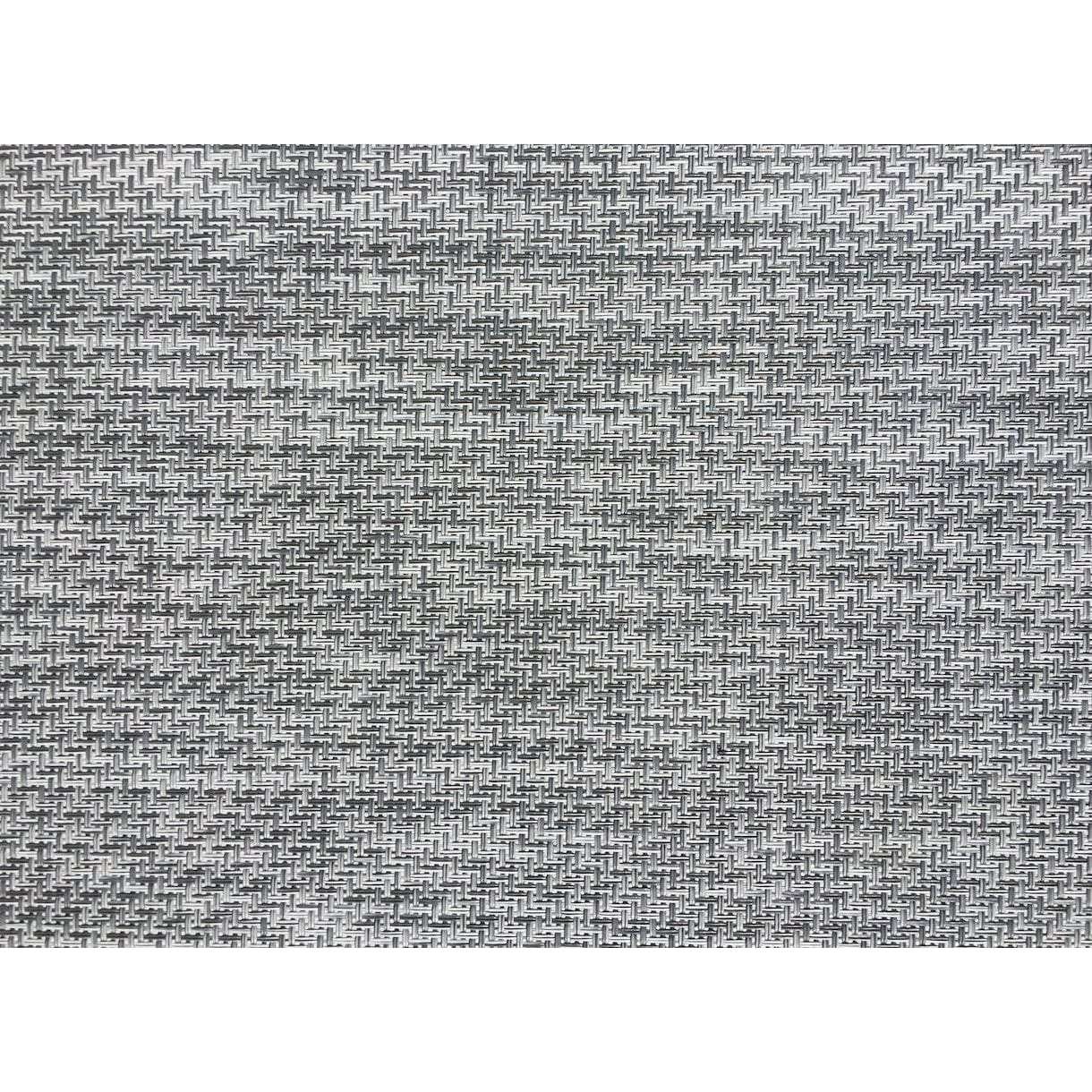

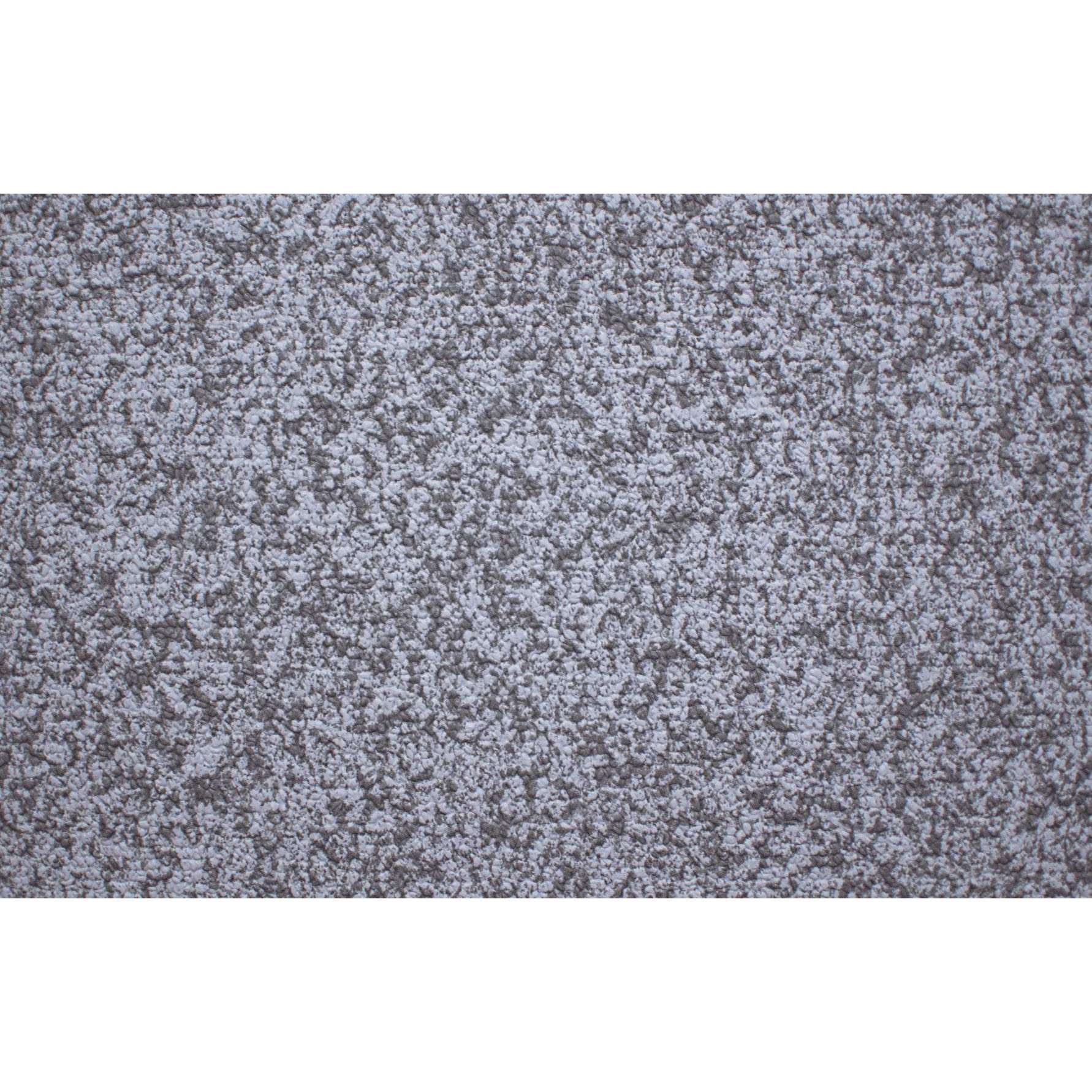

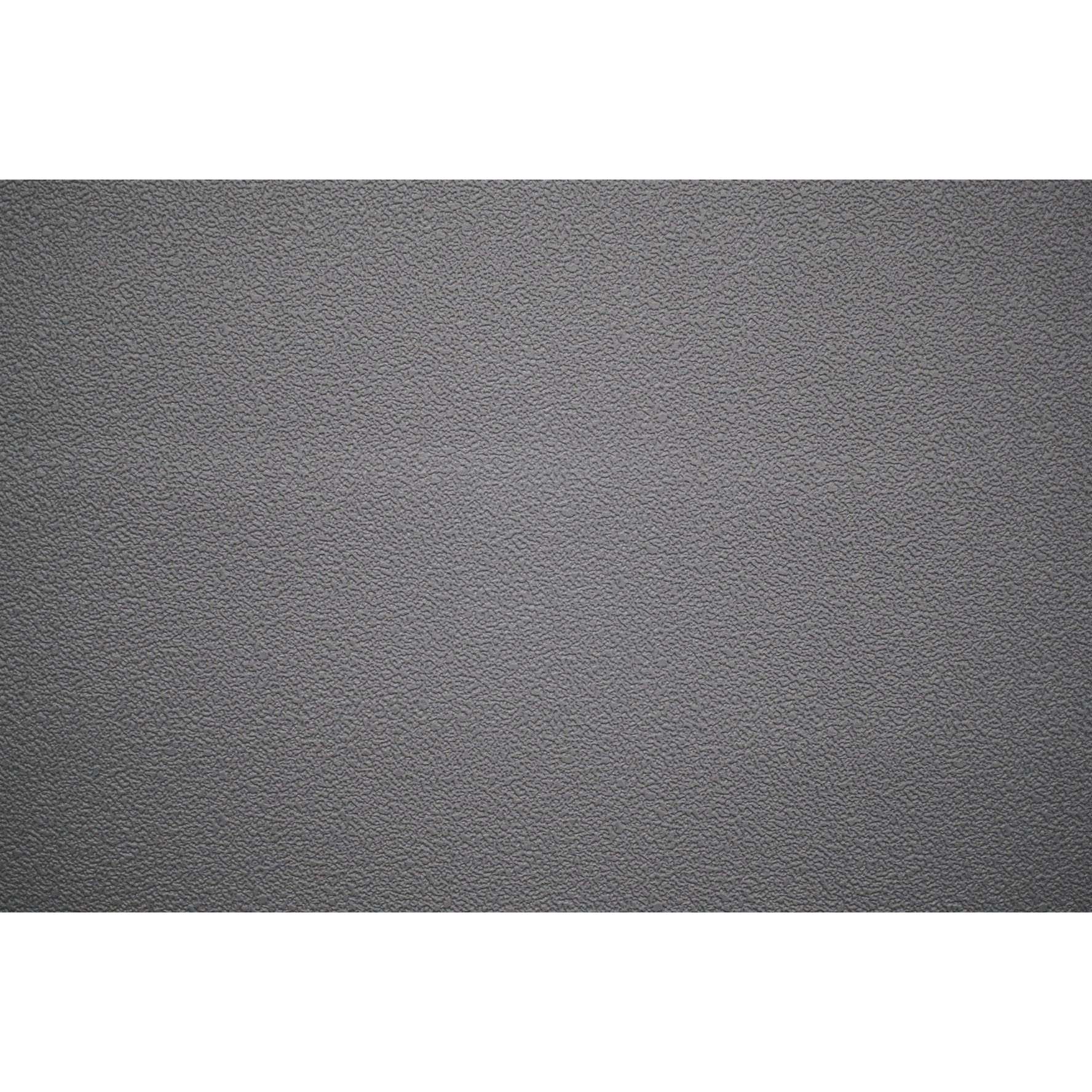

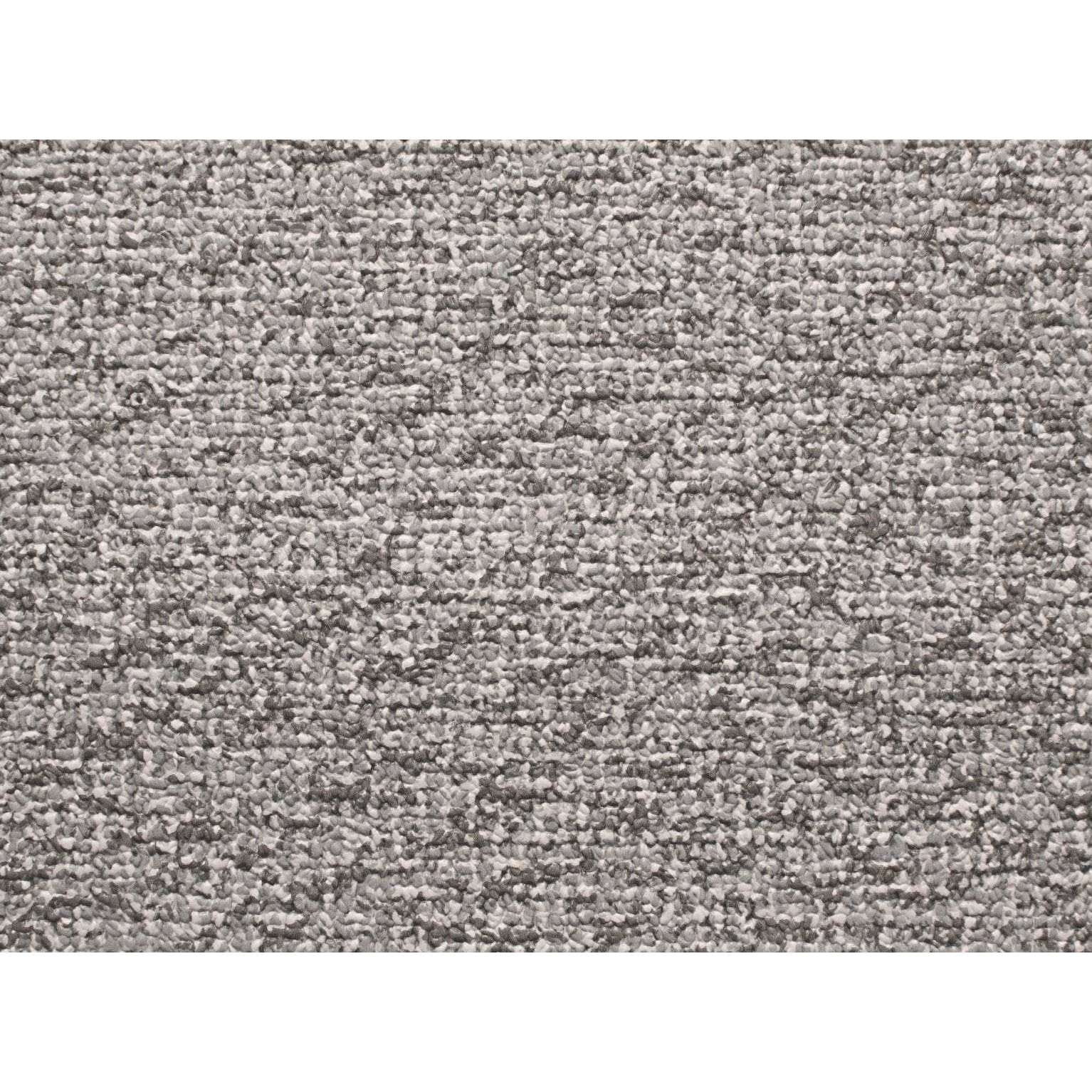

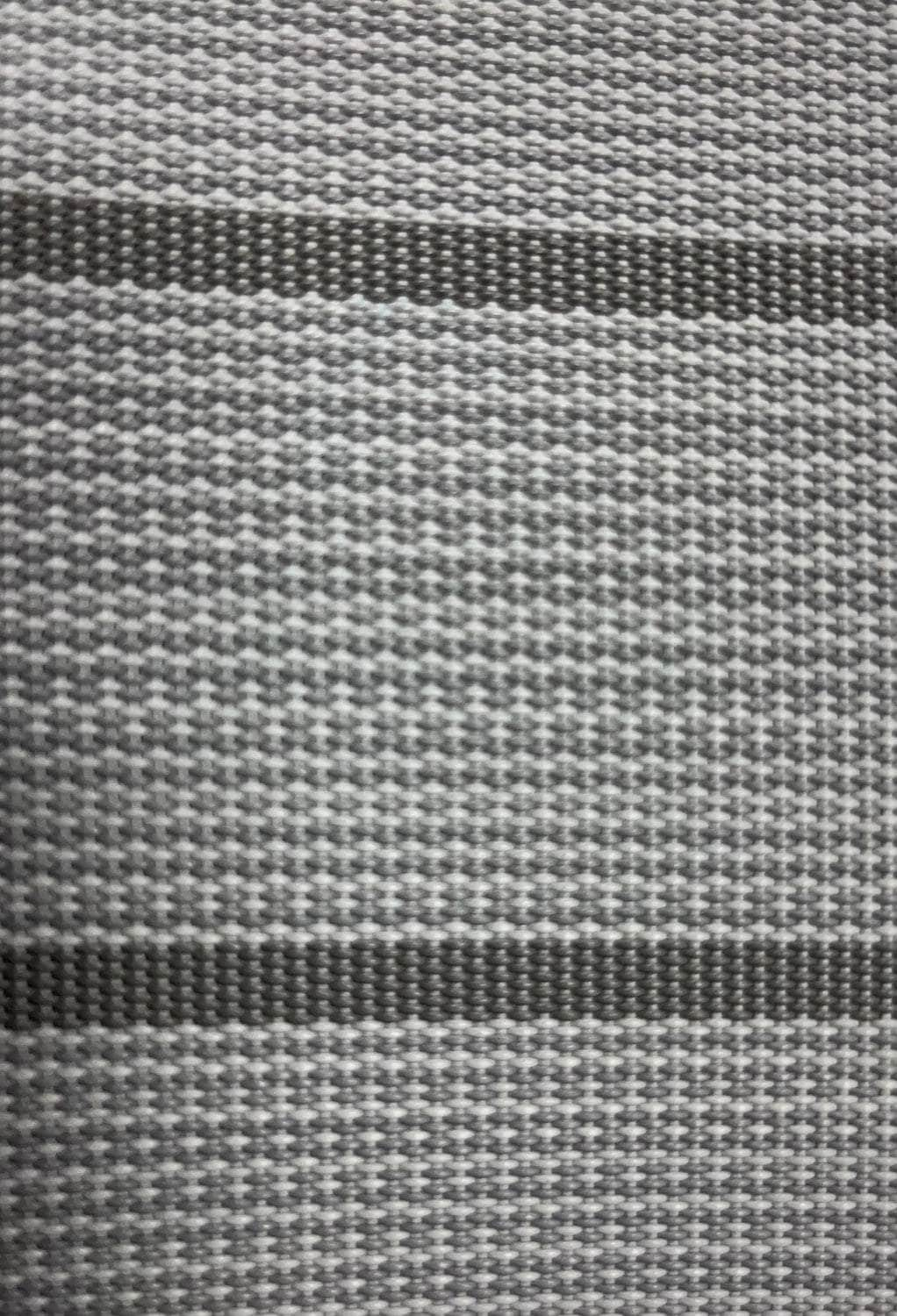

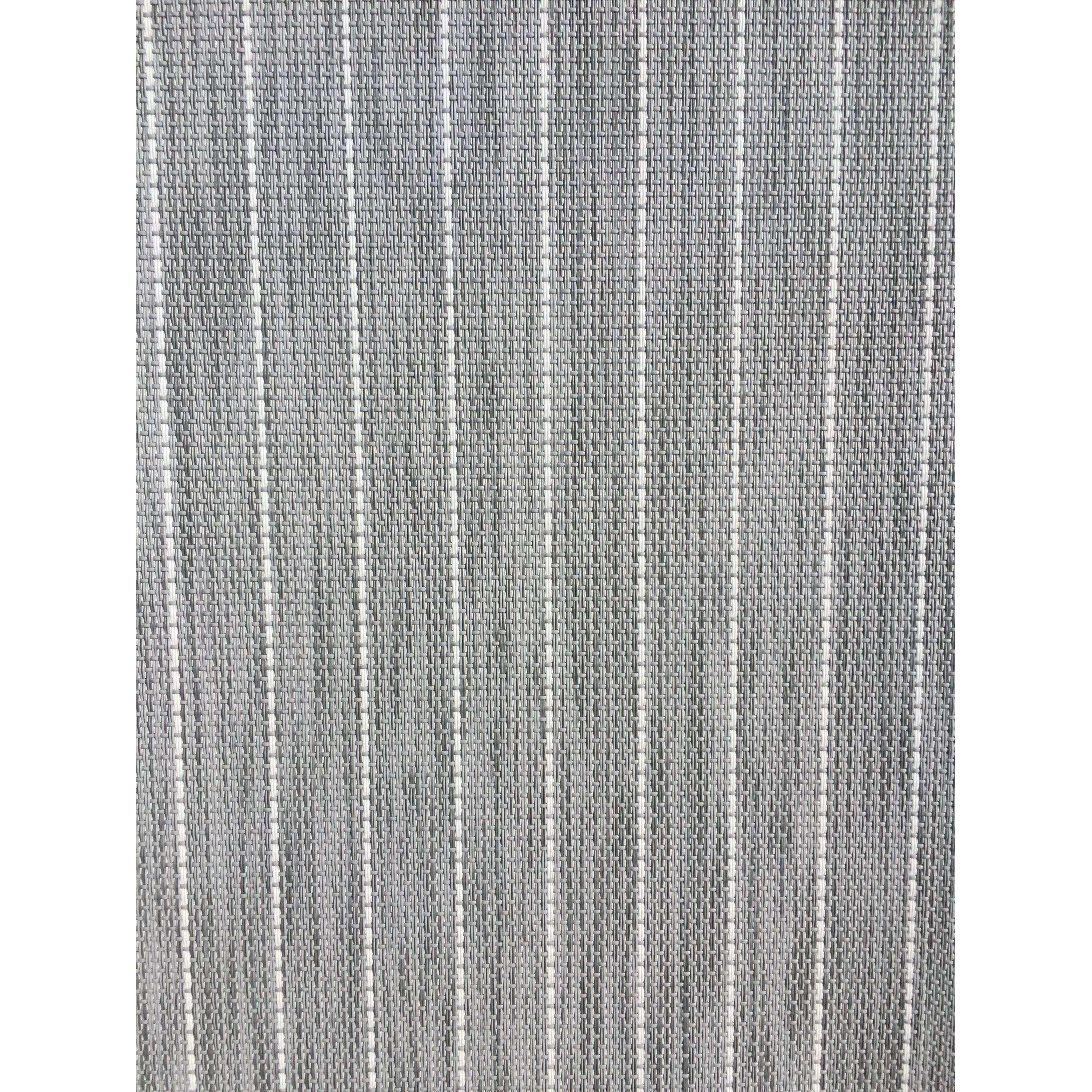

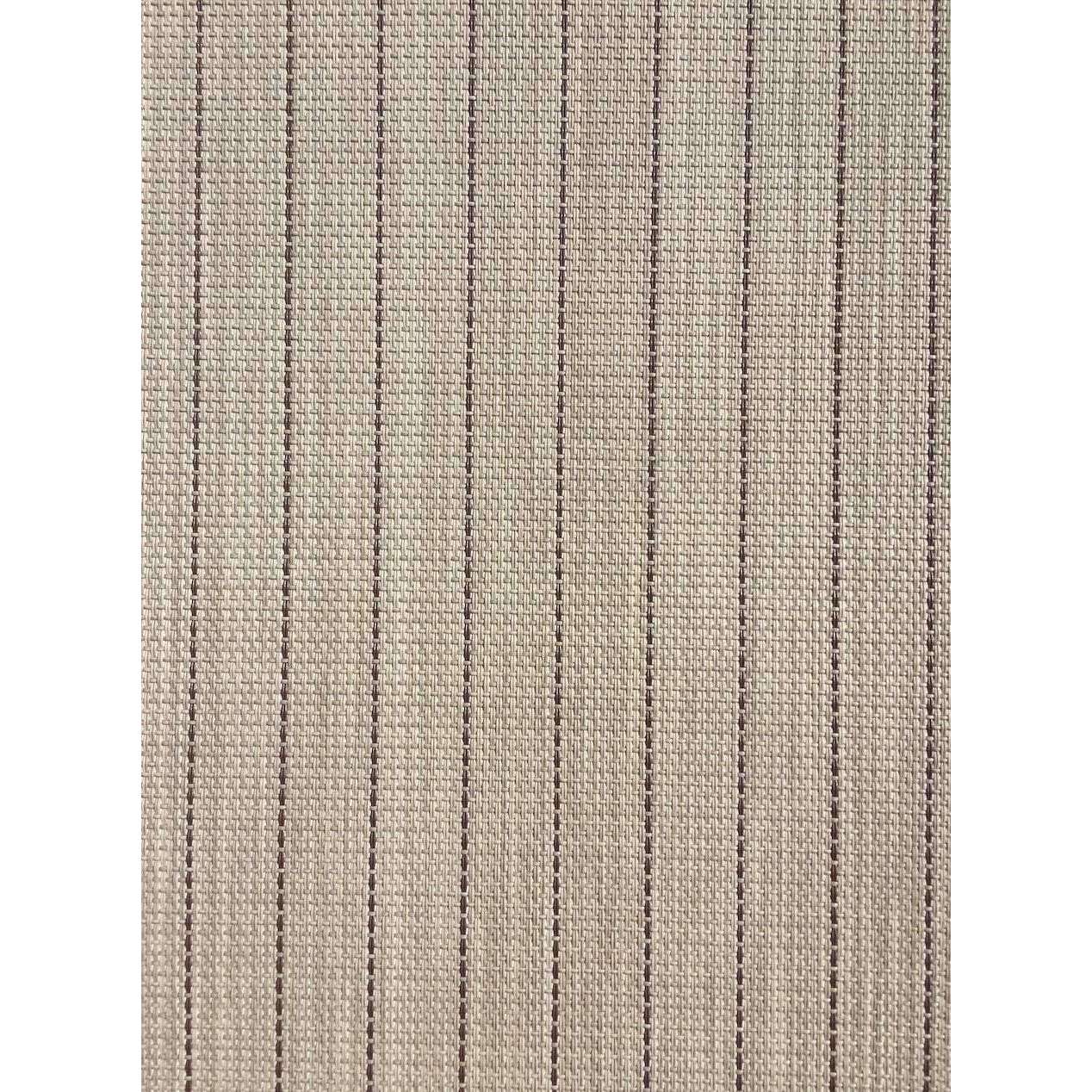

Marideck Marine Flooring - Premium Solid PVC Flooring

Marideck Marine Flooring - Premium Solid PVC Flooring

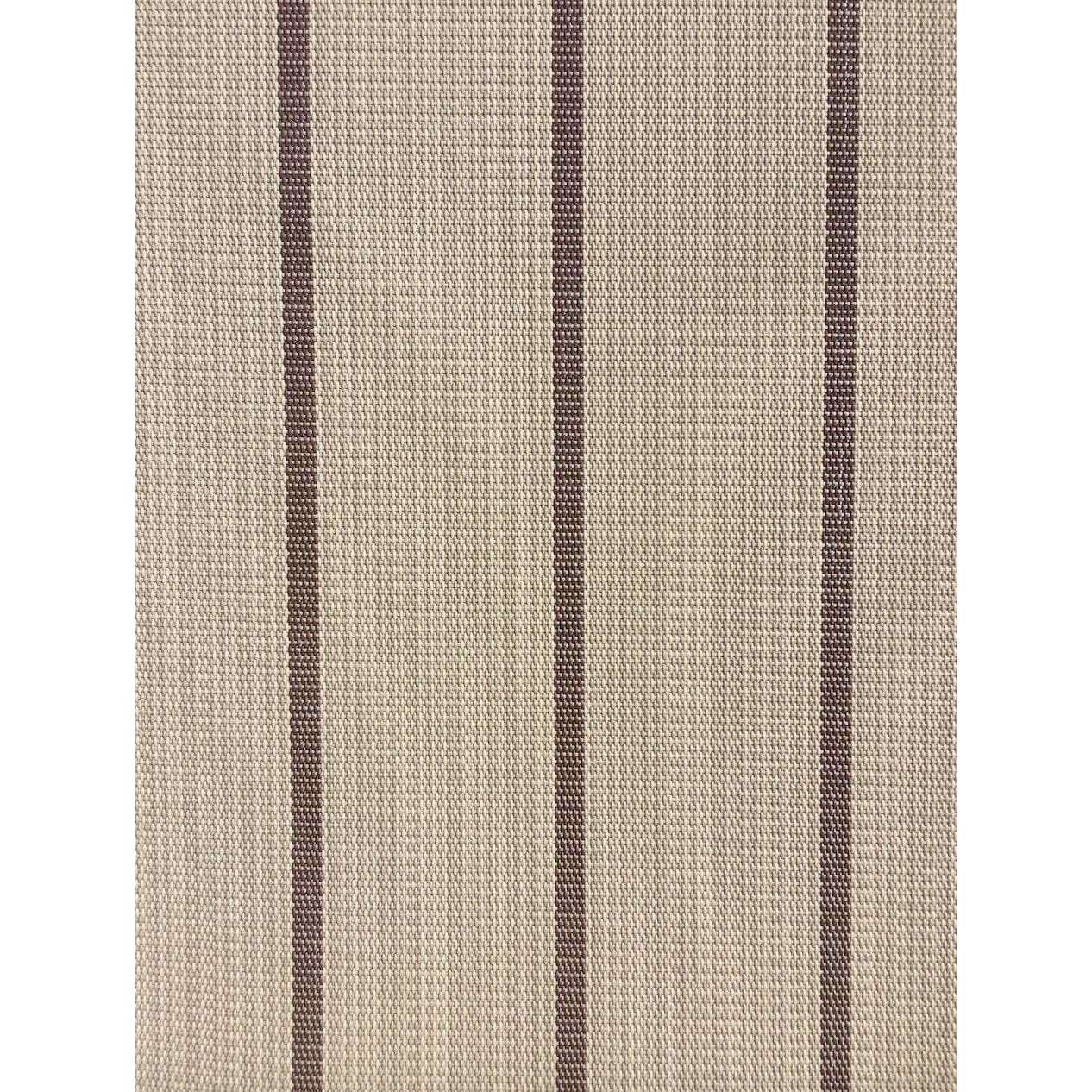

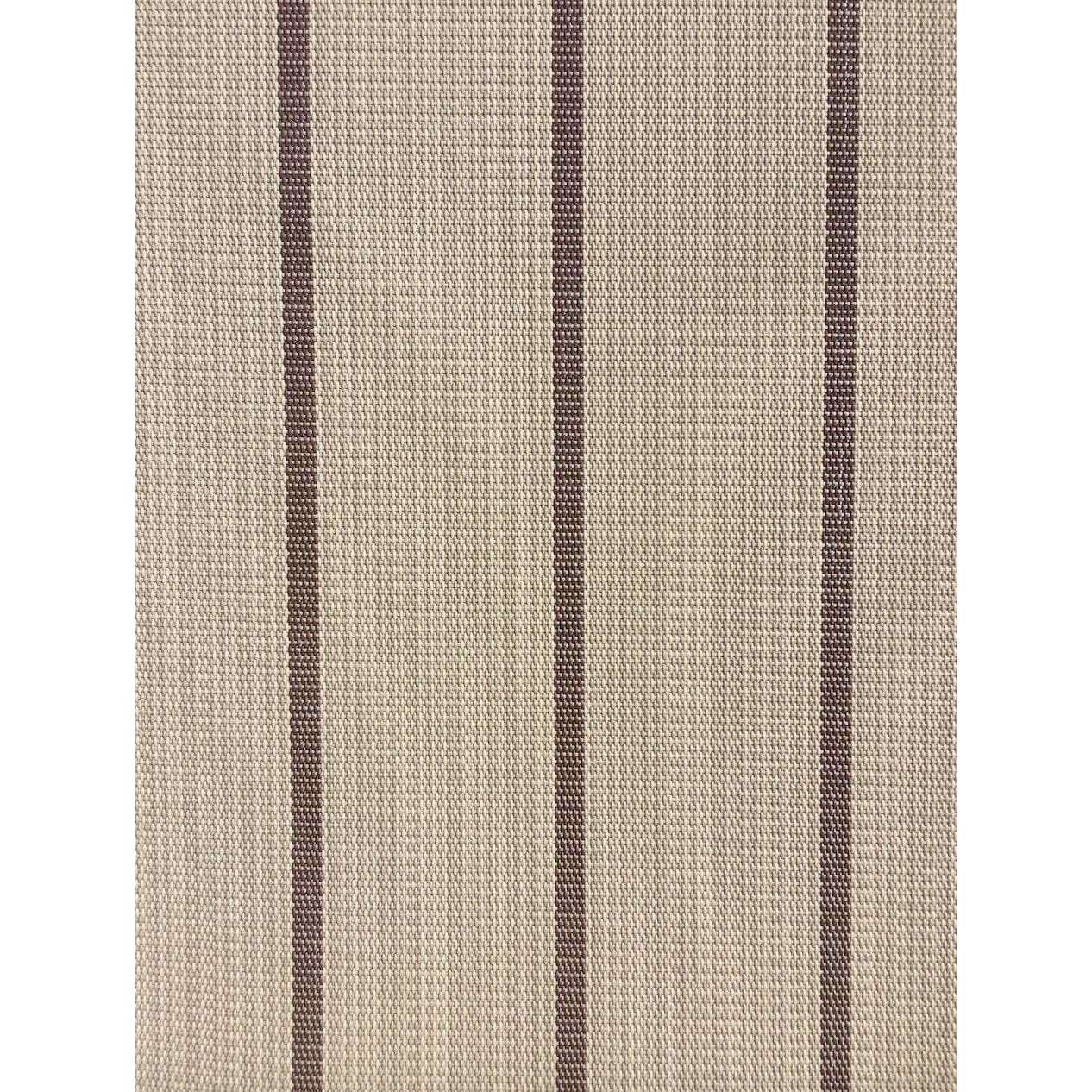

2 inch spacing between stripes

Feet:

3 = 3FT x 102”

4 = 4FT x 102”

5 = 5FT x 102”

6 = 6FT x 102”

7 = 7FT x 102”

8 = 8FT x 102”

9 = 9FT x 102”

10 = 10FT x 102”

11 = 11FT x 102”

12 = 12FT x 102”

13 = 13FT x 102”

14 = 14FT x 102”

15 = 15FT x 102”

16 = 16FT x 102”

17 = 17FT x 102”

18 = 18FT x 102”

19 = 19FT x 102”

20 = 20FT x 102”

21 = 21FT x 102”

22 = 22FT x 102”

23 = 23FT x 102”

24 = 24FT x 102”

25 = 25FT x 102”

26 = 26FT x 102”

27 = 27FT x 102”

28 = 28FT x 102”

29 = 29FT x 102”

30 = 30FT x 102”

31 = 31FT x 102”

32 = 32FT x 102”

33 = 33FT x 102”

34 = 34FT x 102”

35 = 35FT x 102”

36 = 36FT x 102”

37 = 37FT x 102”

38 = 38FT x 102”

39 = 39FT x 102”

40 = 40FT x 102”

Total: $ 16.99

Shipping calculated at checkout.

Now you can get stylish marine flooring built for the outdoors. This Water Resistant and Slip Resistant flooring will keep you and your boat safe from slippery water. Watch water bead up on the surface of this amazing piece of art. Make any boat look like new by updating the floor. Clean up spills and other messes easily. UV treated for maximum sun exposure.

Please note this item takes longer to process and ship due to its size. Most orders are received in about 7-10 business days.

3 Foot Minimum

Marideck Flooring should be installed with Marideck Flooring Glue

WARNING: Prop 65 Disclaimer

WARNING: Prop 65 Disclaimer

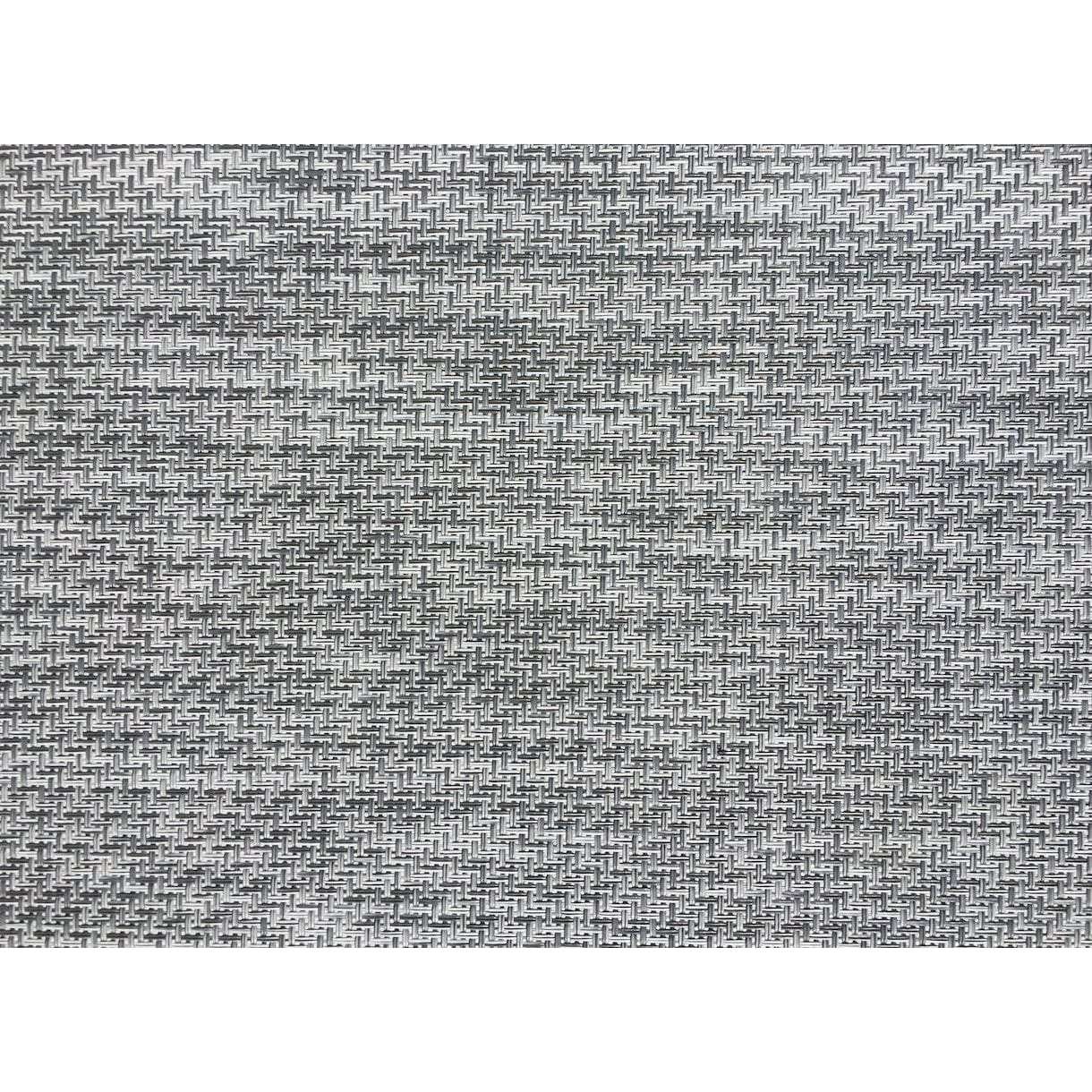

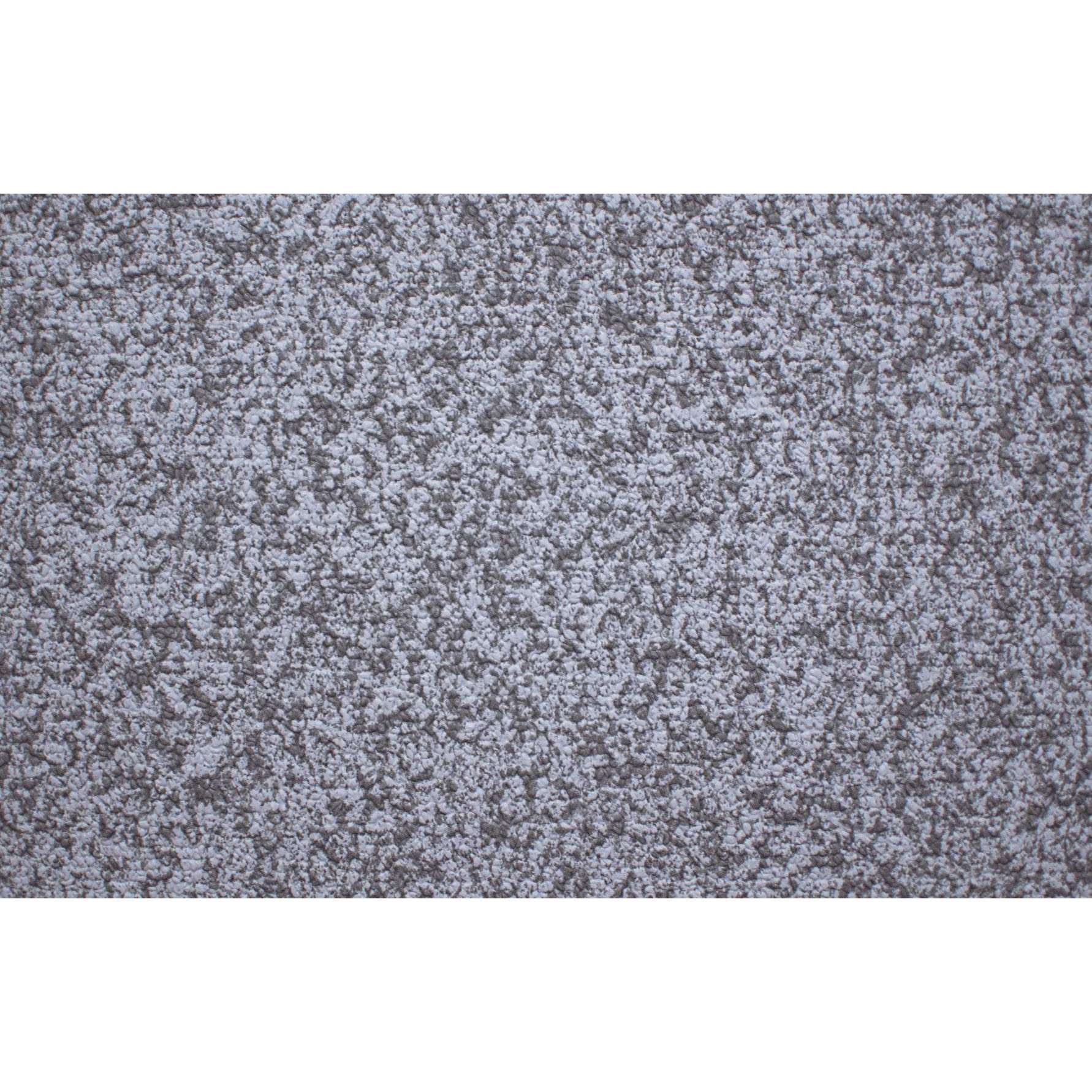

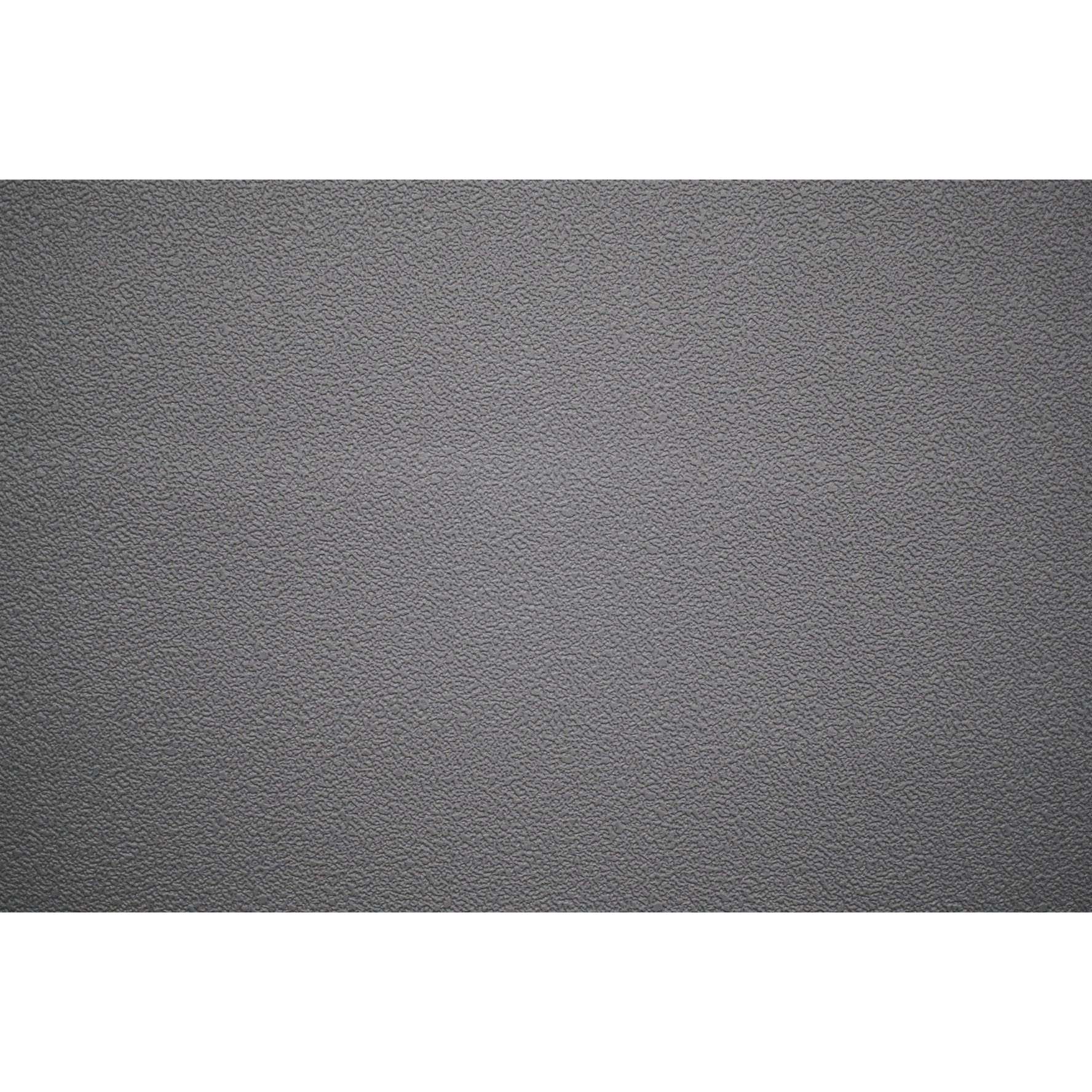

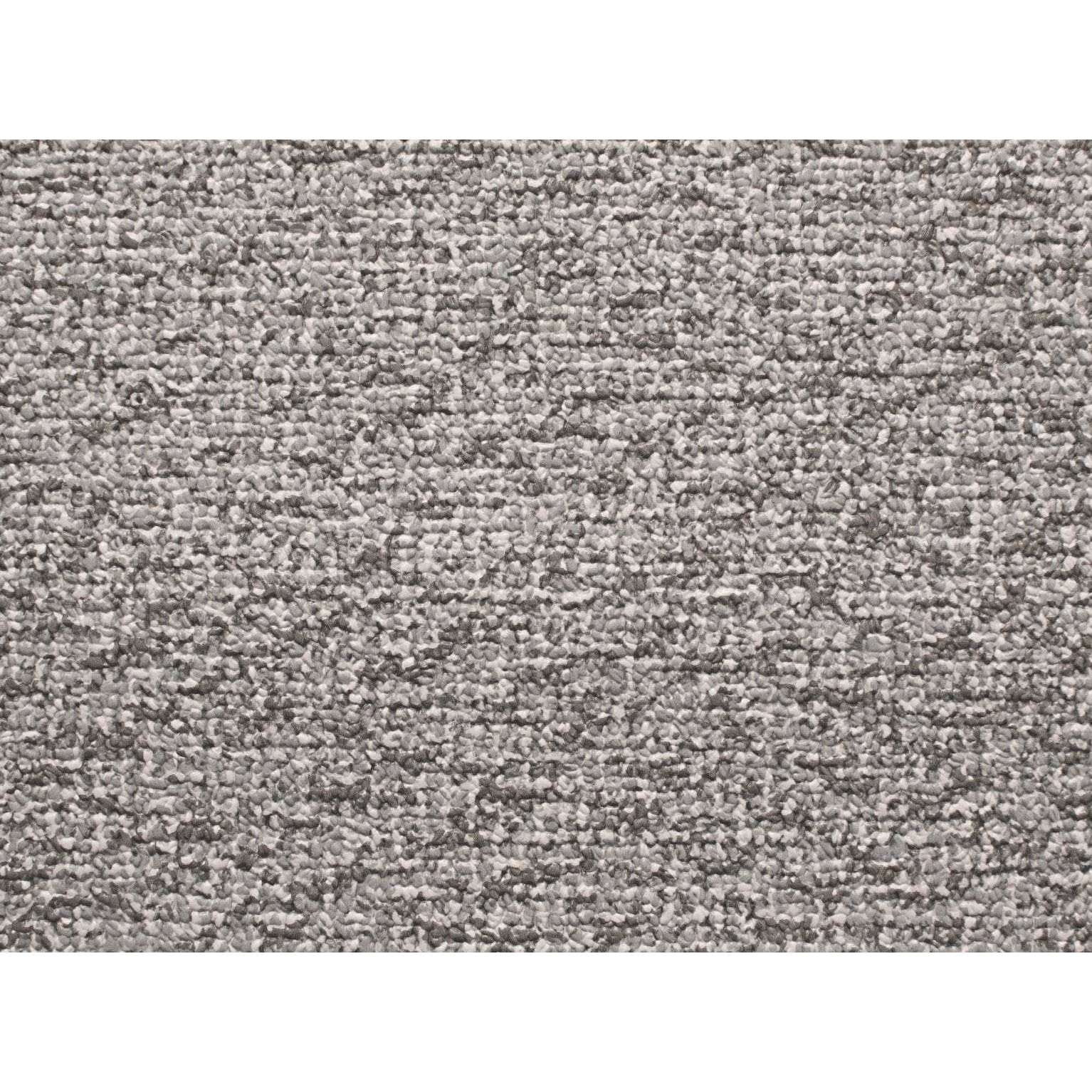

| Specifications | 34 Mil 72" | 34 Mil 102" | 80 Mil 102" | Woven 102" |

|---|---|---|---|---|

| Thickness | 34 Mil | 34 Mil | 80 Mil | 80 Mil |

| Width | 72" | 102" | 102" | 102" |

| Weight (Per Linear Ft) | 2 lbs. | 2.4 lbs. | 4.4 lbs. | 4.8 lbs. |

| Max Roll Length | 75 feet | 62 feet | 33 feet | 31 feet |

| Tensile Strength (lb/in) | 46.5 | 46.5 | 92.5 | 92.5 |

| Lap Joint Strength >100% of Membrane Strength | Pass | Pass | Pass | Pass |

| Tear Strength (exceeds 10 lbs) | Pass | Pass | Pass | Pass |

Marine Vinyl Fabric warrants to the original retail purchaser, that the membrane is free from defects at the time of manufacturing. We further warrant that the membrane, installed to our published specifications, will be free from defects for a prolonged period of two (2) years from the date of purchase, providing the membrane was properly installed, maintained, and used for its intended purpose. At no time during the life of this limited warranty, shall MarineVinylFabric’s liability exceed the original selling price of the membrane. It is specifically noted that any other components of the boat are not covered under this warranty. Labor costs are not covered under this warranty.

Owner shall provide Marine Vinyl Fabric with written notice of any defect in the membrane within fifteen (15) days of discovery. Should the subsequent investigation reveal that the problem(s) were caused by something other than a defect in the membrane, the owner shall be responsible for the cost of investigation made by Marine Vinyl Fabric.

This warranty shall not be applicable for any damage to the membrane resulting from, but not limited to:

1. Natural disaster, including but not limited to earthquakes, lighting, hail, high winds, tornados, hurricanes, etc.

2. Intentional acts, negligence, stains, scuffs, ice or snow removal, failure of Owner to use reasonable care, animals, fires, malicious mischief, vandalism, civil disobedience or improper Original Equipment Manufacturer (OEM) installation error.

3. Settling, warping or other failure of the structure on which the membrane is attached.

4. Alkaline attack, hydrostatic pressure or moisture from the subfloor.

5. Normal wear and tear (i.e. fading, abrasion, etc).

This warranty shall be null and void if:

1. There is a change in the use of the boat by the Owner or authorized user, which affects the membrane installation.

2. The membrane is exposed to substances or chemicals which are not compatible with the membrane and have not been previously approved in writing by Marine Vinyl Fabric.

3. Owner fails to pay the cost of investigation and repair of non-warranted problems.

4. The membrane is damaged, penetrated, torn or altered in any way.

Marine Vinyl Fabric has no obligation under this warranty unless:

1. The bills for membrane have been paid in full to Marine Vinyl Fabric, LLC, the OEM or dealer.

2. Marine Vinyl Fabric agents or authorized installers are allowed access to said installation, to make inspections, during regular working hours.

3. Owner has exercised reasonable care and maintenance in accordance with the recommendations of the manufacturer.

It is expressly agreed that the Owner’s sole remedy to a defect in the membrane is replacement of the defective membrane.

This limited warranty, issued at the office of Marine Vinyl Fabric LLC, 115 Hankes Ave, Aurora, Illinois 60505, and accordingly governed by Illinois law, is not transferable.

NOTE:

Marine vinyl fabric does not warrant products incorporated or utilized in this installation, which is not furnished and specifically disclaims liability, under any theory of law, arising out of the installation or performance of, or damages sustained by or caused by, products not furnished by marine vinyl fabric llc. This limited warranty, given by marine vinyl fabric, supersedes, and is in lieu of all other warranties or guarantees, whether written or oral either expressed, implied or statutory, including the implied warranties or fitness for a particular purpose and merchantability, which extend beyond the face of this certificate. Marine vinyl fabric shall not be liable for any incidental, special or consequential damages including, but not limited to, loss of profits, damage to the boat or its contents, under any theory of law. No representative of marine vinyl fabric has any authority to bind marine vinyl fabric with any representation or warranty other than is stated herein.

Choose options

Frequently Asked Questions (FAQ'S)

For general cleaning, Use a mild dish soap in warm water with a soft bristle deck brush

Rinse the floor thoroughly after scrubbing.

For ground in dirt, mildew, or minor stains, try Orange Glo, Citrus Magic or Simple Green cleaners.Spray the area that is stained with the cleaner and let it soak for about 10 minutes before using a paper towel or microfiber towel to wipe up the area.

AVOID IF POSSIBLE - For tougher stains, you can try CLR or Tilex DO NOT allow these cleaners to sit on your floor for an extended length of time. Rinse the sprayed area well a few times to make sure it is completely rinsed off . BE SURE THESE CLEANERS DO NOT GET ON SEATS OR CANVAS AS THEY WILL CAUSE DAMAGE.

Regardless of which cleaner you choose to use, carefully read each cleaner’s instructions and recommended use.Minimize potential damage to your flooring by testing harsher cleaners on a concealed section of your boat floor before using the cleaner on a more obvious section of the floor. If unsure, contact the manufacturer and ask if the cleaning product is safe to use on vinyl.

For a smooth and successful application, you'll need to thoroughly prepare the boat surface. This includes:

- Removing all objects: Take off seats, tables, electronics, etc., to allow easy access for vinyl application.

- Ripping out old flooring: Completely remove existing carpet, vinyl, and any remaining adhesive residue.

- Replacing rotten wood (pontoons): For wood decks, especially pontoons, ensure a solid foundation by replacing any damaged wood with new ¾” pressure-treated plywood or marine-grade plywood screwed securely to the boat structure.

- Cleaning the surface: Clear away any debris, sawdust, screws, or foreign objects using a leaf blower or broom.

Preparation:

- Clean the surface: Thoroughly remove all debris, dust, screws, and foreign objects from the boat area using a leaf blower or broom.

- Fiberglass etching (optional): For fiberglass surfaces, roughen the surface with coarse sandpaper to improve adhesion. Clean any fiberglass dust after sanding.

- Measure and cut the vinyl: Carefully measure and pre-cut the vinyl pieces to the required shapes and sizes for optimal coverage.

Safety:

- MD-102 is flammable. Keep it away from children and open flames/high heat. Use it in a well-ventilated area.

Adhesive Application:

- Apply adhesive to vinyl: Use a small nap paint roller to spread MD-102 adhesive on the non-woven polyester back of the vinyl (3-inch roller for smaller areas). Avoid getting adhesive on the vinyl's topside.

- Apply adhesive to surface: Apply a thin, even coat of MD-102 to the boat surface where the vinyl will be placed.

- Set time: Allow both the adhesive on the vinyl and the boat surface to set for 10-15 minutes until it's slightly tacky to the touch.

Note: Applying too much adhesive can cause air bubbles under the vinyl. These bubbles will disappear in 2-3 days, especially in sunlight. Don't remove the vinyl or seal the edges during this time.

- MD-101 (wood surfaces) dries in 2-3 hours.

- MD-102 (aluminum/fiberglass surfaces) dries in 1 hour.

- Allow the adhesive to dry completely overnight before installing seating or equipment.

Here's a step-by-step guide for installing the vinyl on a prepared wood surface using MD-101 adhesive:

- Unwrap and position the vinyl: Carefully unroll the vinyl, checking for sufficient length and centering it on the surface with appropriate overhang on all sides. Remove any wrinkles.

- Secure one end and roll back: Place weighted objects (toolbox, pail) near one boat end to hold the vinyl down. Starting from the opposite end, loosely roll the vinyl back towards the weights, maintaining a straight roll.

- Apply the adhesive: Shake the MD-101 container for a minute. The glue should resemble thick white paint. Apply the adhesive in serpentine lines (about 1.5” wide) using a roller, covering an area wider than the vinyl by 15 inches. Ensure a heavy coat with no puddles or dry spots.

- Unroll and press the vinyl: Standing on the vinyl near the weights, slowly unroll it over the wet adhesive, removing any wrinkles by lifting the vinyl slightly. Use a stiff bristle broom to press the vinyl down, ensuring even adhesive distribution and removing air pockets.

- Repeat for remaining area: Return to the beginning, remove the weights, fold back the vinyl, and apply adhesive as before. Overlap the new adhesive section slightly over the previous one. You can lift the adhered vinyl slightly to ensure complete adhesive coverage. Repeat until the entire surface is covered.

Vinyl Installation:

- Position and apply vinyl: Carefully place the vinyl on the surface without wrinkles or air bubbles. MD-102 requires quick application, so ensure proper positioning before pressing down.

- Smoothing: Once placed, use your hand to smooth out any air bubbles or wrinkles, ensuring uniform contact with the surface.

- Repeat for remaining pieces: Follow the same steps to apply subsequent pieces of vinyl.

Seams:

- Overlapping seams is possible, but minimizing exposed seams is recommended. Try to hide seams under overhangs, seats, or align them with existing seams in the aluminum.

- For butt seams, use a "wallpaper cut": Overlap the vinyl pieces, then use a sharp utility knife to cut through both layers along the top vinyl's edge. Remove the bottom vinyl piece and press the top vinyl down for a clean butt joint.

By following these steps, you can successfully apply marine vinyl fabric to your aluminum or fiberglass boat surface using MD-102 adhesive. Remember to prioritize safety and take your time for a professional-looking finish

Customer Testimonials

Other Products You May Also Like

Learning Resources

From Pontoons to Kayaks: Marine Vinyl Solutions for All Boat Types

Boat owners face constant challenges in protecting their vessels from sun, water, and everyday wear. Marine vinyl offers a smart, versatile solution across a wide range of boat types—from pontoons ...

Read more

The 3 Best Boat Flooring Options You Should Know

Picking out the best boat flooring can be like finding a needle in a haystack. You probably don’t know where to start, and don’t know what to look for when it comes to the top boat flooring. Let u...

Read more

5 Steps to Maintain Vinyl Boat Flooring

If you’ve made the investment to install vinyl flooring on your boat, you’ll want to make sure that you’re taking the right steps to maintain your vinyl flooring. Vinyl boat flooring is an awesome...

Read more