Winterize Your Porch: Easy DIY Ideas to Keep It Cozy

As soon as winter rolls in, most porches, patios, and screened-in spaces sit empty until spring. Cold air, drafty flooring, and exposure to snow or rain quickly make these areas unusable. But with ...

Read more

How to Convert Your Patio to a Sunroom Without a Major Renovation

A sunroom is one of the most desirable home upgrades—bright, relaxing, and usable almost all year long. But for most homeowners, the idea of turning an open patio into a fully enclosed sunroom feel...

Read more

How to Weatherproof Your Porch Before Winter Hits

When temperatures begin to drop, many homeowners abandon their porches until spring returns. Cold drafts, moisture, and snow make outdoor spaces uncomfortable in winter—but with a few smart upgrade...

Read more

DIY Clear Vinyl Panels for Screened Porches: Materials, Tips & Tricks

A screened porch is one of the best places to relax at home—fresh air, natural light, and all the outdoor vibes without the bugs. But when cold weather, heavy rain, or strong winds hit, even the co...

Read more

DIY Indoor Greenhouse: Tips and Ideas

Not everyone has the yard space—or the right climate—for an outdoor greenhouse. Long winters, small apartments, or urban living can make it tough to keep plants alive, let alone thriving. But that ...

Read more

Greenhouse Vinyl vs Polycarbonate: Which Is Better for Your Plants?

When it comes to building or upgrading a greenhouse, one of the most important decisions is what material you’ll use for the covering. The “skin” of your greenhouse determines how much sunlight you...

Read more

How to Build a DIY Greenhouse on a Budget

A greenhouse is every gardener’s dream—a protected, sun-filled space that lets you grow vegetables, herbs, and flowers long after the frost sets in. The catch? Prefabricated greenhouses can cost th...

Read more

How to Reupholster RV Furniture Yourself

Reupholstering RV furniture is one of the most cost-effective ways to give your interior a fresh, modern look. Whether it’s a dinette, sofa, or captain’s chair, a DIY reupholstery project can save ...

Read more

Best DIY Bunk End Covers for Pop-Up RVs: Materials & Instructions

Bunk end covers (also called “bunk end caps” or “awning covers”) are essential for pop-up RVs. They protect your sleeping areas from rain, sun, and debris while adding insulation and privacy. Inste...

Read more

Best Fabric for RV Upholstery: What the Pros Recommend

RV upholstery needs to handle heavy use, fluctuating temperatures, and exposure to sunlight. Choosing the wrong fabric can lead to fading, cracking, or constant cleaning headaches. Here’s what the ...

Read more

RV Renovation Ideas That Add Style and Function

Renovating your RV doesn’t have to mean a full gut job. Small, strategic upgrades can dramatically improve both style and functionality. Whether you’re updating a dated interior or preparing for a ...

Read more

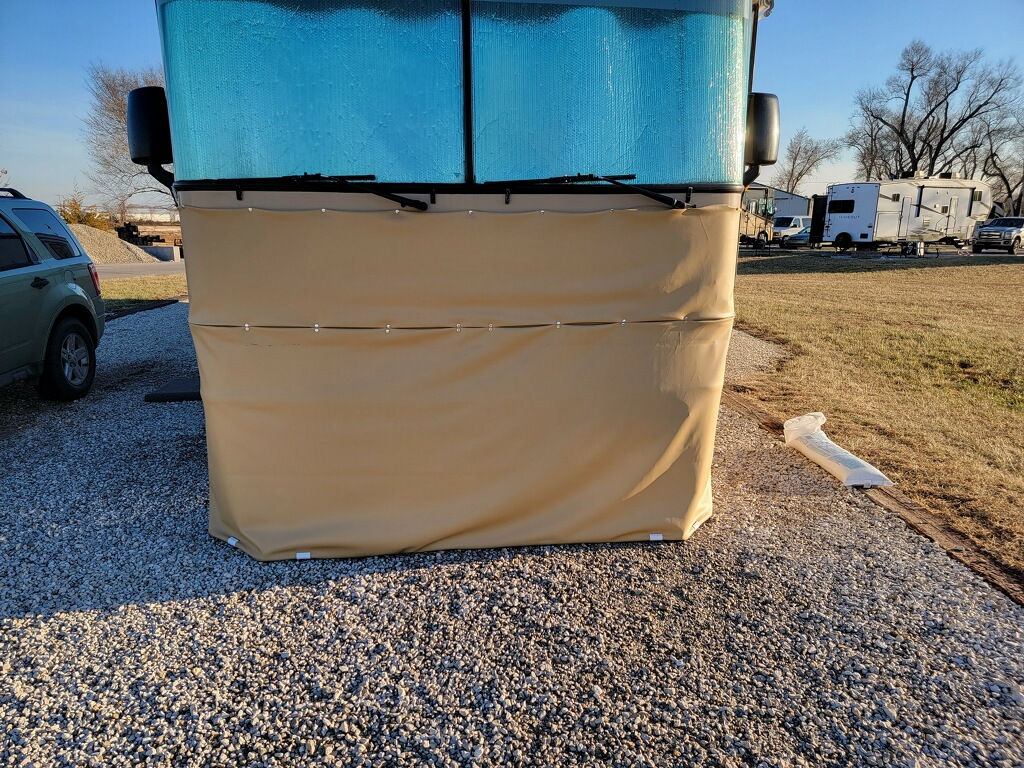

The Ultimate Guide to DIY RV Skirting for All Seasons

RV skirting is a smart, cost-effective way to protect your RV year-round. Whether you’re camping through winter or trying to keep your RV cool in the summer, the right skirting creates a more comfo...

Read more

FR vs. Regular Clear Vinyl: When Do You Need Flame-Retardant Protection?

Choosing the right type of clear vinyl can impact more than just cost—it can affect safety, compliance, and performance. If you’re working in a commercial space, public facility, or anywhere near a...

Read more

Choosing the Right Vinyl Gauge for Porch Windows, Greenhouses, and More

Selecting the correct vinyl gauge for outdoor applications like porch windows, greenhouses, and patio enclosures is essential for ensuring durability, clarity, and weather resistance. Homeowners an...

Read more

Bringing the Light In: Using Clear Vinyl for Enhanced Visibility on Your Boat

Clear visibility stands as a crucial factor for safe boating. Many boat owners face challenges with poor visibility during rough weather or low-light conditions. The right clear vinyl windows can m...

Read more

Crystal Clear Views: Why Boat Owners Choose Marine-Grade Clear Vinyl

Cloudy or scratched boat windows can ruin a day on the water—and create serious safety risks. Marine-grade clear vinyl provides a durable, transparent solution for boat enclosures, offering long-te...

Read more

From Pontoons to Kayaks: Marine Vinyl Solutions for All Boat Types

Boat owners face constant challenges in protecting their vessels from sun, water, and everyday wear. Marine vinyl offers a smart, versatile solution across a wide range of boat types—from pontoons ...

Read more

Beyond The Boat: Unexpected Uses For Flexa Marine Vinyl Fabric

Most people think marine vinyl fabric belongs only on boats. They see it covering seats on fishing vessels or lining the interiors of luxury yachts. This tough material serves boat owners well, but...

Read more

How to Install Marine Vinyl Boat Flooring Like a Pro

Old boat flooring needs an upgrade from time to time. Worn-out carpets and damaged surfaces can make a boat look shabby and reduce its value. Many boat owners face this common problem but hesitate ...

Read more

Marine Vinyl vs. Leather vs. Canvas: The Ultimate Showdown for Your Boat

Choosing the right material for boat seats can make or break your time on the water. Marine vinyl, leather, and canvas each offer distinct strengths, but their differences in comfort, durability, a...

Read more

How to Remove Wrinkles from Vinyl: Heat vs. Sunlight Methods

Vinyl is one of the most versatile materials out there—whether it’s marine flooring, upholstery, or banners, its durability and flexibility make it a go-to choice. But there’s one thing that can th...

Read more

Clear Vinyl Fabric DIY Ultimate Guide

Not all clear vinyl fabrics are the same. This comprehensive guide dives into the differences seen in the vinyl and shows you how to pick the perfect clear vinyl for your specific needs. With our...

Read more

You spent a lot of money on your marine vinyl, so you must take the right steps to protect it and prevent damage. Repairing damages and removing stains is difficult to do, so be sure to take the ...

Read more

How to Clean Marine Vinyl Flooring

Maintaining and cleaning your marine vinyl flooring is important to keep it looking fresh and to maintain a high level of quality. In this post, we’re going to go over the best ways to clean your...

Read more

Replacing Marine Vinyl on Pontoon Seats : Step-by-Step Guide

If the marine vinyl on your pontoon seat is in rough shape, you may need to look at getting it replaced. Don’t worry though, it doesn’t have to be a daunting project or time investment. When mari...

Read more

It is important to take proper care of your vinyl windows. This will help prolong the life of your windows and keep them looking nice. Vinyl windows should be cleaned at least twice a year to keep ...

Read more

5 Ways to Remove Wrinkles from Marine Vinyl

One problem you may run into when it comes to marine vinyl is that creases can form which creates wrinkles in the vinyl. The good news is that in most cases, the wrinkles in the marine vinyl fabr...

Read more

Everyone always seems to ask us what is the best way to clean clear vinyl without risking damage. After manufacturing and selling clear vinyl for nearly 10 years, we have found the following meth...

Read more

Top 12 Ways to Use Clear Vinyl in Your Everyday Projects. Clear vinyl, a versatile plastic material known for its transparency, durability, and flexibility, finds a multitude of applications acros...

Read more

The 3 Best Boat Flooring Options You Should Know

Picking out the best boat flooring can be like finding a needle in a haystack. You probably don’t know where to start, and don’t know what to look for when it comes to the top boat flooring. Let u...

Read more

How to Replace Marine Carpet and Install Marine Vinyl Flooring

You have decided to make the switch to marine vinyl flooring for your boat - nice choice! Marine vinyl is a great option and finally, you’ll love it. If you’re replacing all of the carpet on your b...

Read more

How To Prevent Vinyl Boat Seats From Cracking

Marine vinyl fabric holds up really well, but it’s important that you take good care of it. Fading and cracking can occur if you don’t take the right precaution steps to avoid it. I’m going to go...

Read more

How to Clean Marine Vinyl Seats

Keeping your marine vinyl seats clean is important for a variety of reasons. One of the biggest reasons being that it will help extend the life of your boat seats. Your seats will look nice and la...

Read more

5 Steps to Maintain Vinyl Boat Flooring

If you’ve made the investment to install vinyl flooring on your boat, you’ll want to make sure that you’re taking the right steps to maintain your vinyl flooring. Vinyl boat flooring is an awesome...

Read more

How to Clean Marine Boat Flooring?

Maintaining and cleaning your marine vinyl flooring is important to keep it looking fresh and to maintain a high level of quality. In this post, we’re going to go over the best ways to clean your ...

Read more

9 Tips for Sewing with Clear Vinyl

Are you trying to sew with clear vinyl, but aren’t sure where to start? It’s a little different than sewing with other materials, so we put together some tips that should help you get started. So...

Read more

The Ultimate Guide to Choosing the Best Marine Flooring

Congratulations! You're looking for the perfect new marine flooring, and you've come to the right place. We understand the abundance of options can be overwhelming, so we'll guide you through eve...

Read more

The Ultimate Guide For How To Enclose Your Porch With Clear Vinyl

Everything You Need To know About Installing A Clear Vinyl Porch Enclosure..... Hey you! Yes you! Do you have a porch, gazebo, or a hot tub that you want to use all year round? Want to save some mo...

Read more

How to pick the Best Marine Vinyl?

Learn how to pick out and identify great quality marine vinyl. This guide will help you identify the best vinyl for your project.

Read more

We pride ourselves on our quality service and product and this honor backs up our commitment to you.

Read more

Meet Robert From JCG Designs! Robert Is a professional with 40 years of experience. Learn from the master.

Read more

9 Easy Steps To Make An Ice Fishing Bucket Seat

Winter is officially here so that means it's ice fishing time! Don't worry spring will be here before you know it and we can go fishing from our boats soon enough. While there is still ice outside ...

Read more

Meet Flexa Marine Vinyl! Besides being great for boat seats and upholstery this athletic PVC Vinyl is a High Endurance material that is manufactured for gyms and workout equipment. This durable Ath...

Read more

Have you ever gone to a tropical resort and laid in one of those beautiful beds on the beach? There are usually only a handful of these beautiful beds that people usually fight over. If you have ev...

Read more

Marine Green and Recycle Clean

Our main mission is to bring you the highest quality marine vinyl at affordable rates, but how we do that is equally important. We want to help keep this planet green and clean. This is why we do o...

Read more

Marine Vinyl is a very versatile material. Most people associate marine vinyl with boats, cars and upholstery, but there are many surprising uses for this extremely durable material. Some people ma...

Read more

3 Easy Tips To Sew Marine Vinyl

Sewing Marine Vinyl is actually pretty easy. The biggest difference between sewing Marine Vinyl and other fabrics is the thickness. If the fabric is too thick you will need an industrial sewing mac...

Read more

Some people think Marine Vinyl is popular in only warmer states like Florida and California, but people use Marine Vinyl throughout the United States. Marine Vinyl is most commonly used in outdoor ...

Read more

How To Clean Marine Vinyl Fabric?

Whether you have recently got a boat and you want to keep it in great shape or the more likely option is that you have some mildew or stained seats and you want to get it clean without damaging y...

Read more